Description

Product Description

Big Size QK1327 High Quality CNC Pipe Threading Lathe Machine Pipe Screwing Lathe have a large through-hole on the spindle box, and the workpiece passes through the through-hole and is clamped by two chucks located at both ends of the spindle for rotary motion. There are generally two ways to feed the cutting tool: one is to drive the slide plate and tool holder located in front of the bed by the screw, which is the same as that of a regular lathe; Another method is to use a flat comb blade external thread cutting head (see automatic opening and closing thread cutting head) located on the slide plate in the center of the bed to cut into the workpiece and move forward accordingly. Some machine tools for processing long pipes also come with workpiece support devices, such as center frames, follower frames, rear supports, etc.

Big Size QK1327 High Quality CNC Pipe Threading Lathe Machine Pipe Screwing Lathe

Specification

| SPECIFICATION | Units | QK1327 |

| Swing over bed | mm | 800 |

| Swing over cross slide | mm | 420 |

| Distance between centers | mm | 1000/1500/3000 |

| Pipe threading range | mm | 130-270 |

| Guideway width | mm | 600 |

| Max. load capacity | T | 4 |

| Spindle bore | mm | 220 |

| Spindle speed steps | - | manual. 4 steps |

| Spindle speed range | rpm | 25-89/108-382 |

| Chuck | mm | φ630 4-jaw manual |

| Turret/tool post | - | CNC turret 4 position |

| Tool shank size | mm | 32 x 32 |

| X axis travel | mm | 350 |

| Z axis travel | mm | 850/1350/2850 |

| X axis rapid traverse | mm/min | 4000 |

| Z axis rapid traverse | mm/min | 6000 |

| Tailstock quill diameter | mm | 100 |

| Tailstock quill taper | - | MT6 |

| Tailstock quill travel | mm | 250 |

| Main spindle motor | kW | 15 |

| Weight for 1000 | kg | 4200 |

Product Feature

1. The QK1327 High Quality CNC Pipe Threading Lathe Machine CNC Oil Country Lathe Machine tool has the characteristics of high degree of automation, high efficiency and high precision, wide application range and simple operation

2, CNC pipe screw lathe is my current more common lathe, for the medium CNC lathe in the boutique.

3. The headstock is driven by variable frequency motor with stepless speed change. Domestic well-known manufacturers spindle bearing, domestic well-known brand three jaw chuck.

4, CNC system modular design, easy debugging, easy maintenance, x,z axis using high-power, servo motor, advanced performance, strong reliability.

5, casting bed saddle. Skateboard, internal rib layout is reasonable, the selection of high-precision ball screw produced in Jining, high precision, accurate transmission. Domestic famous brand four-station electric tool holder, high positioning accuracy, strong rigidity, high reliability.

Company Profile

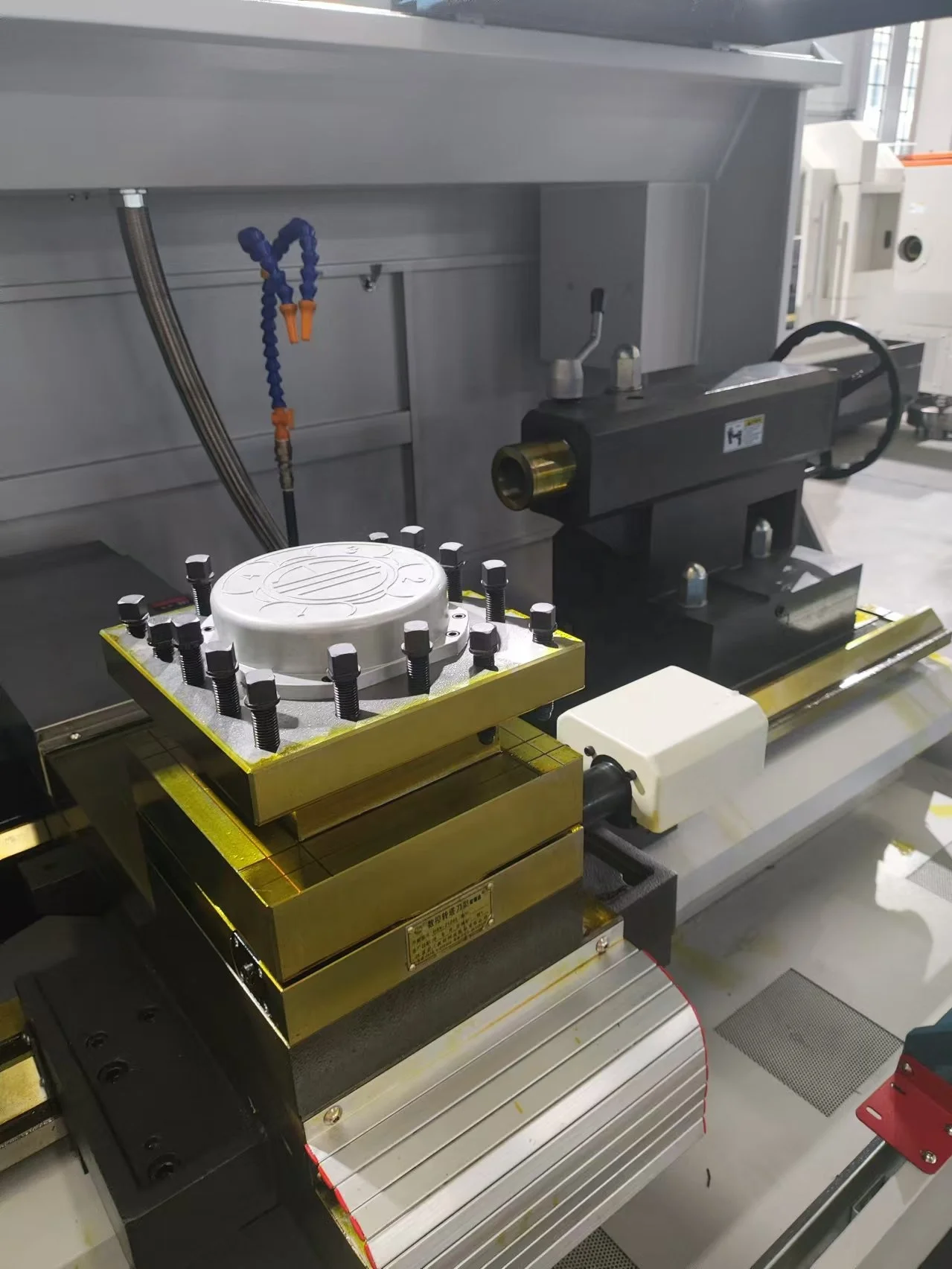

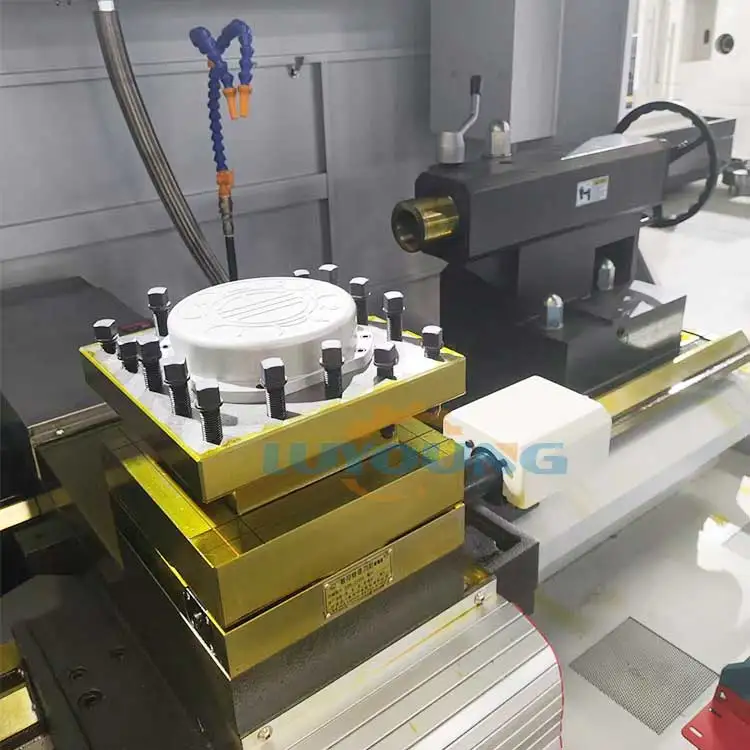

Customer Photos

Luyang CNC machinery company has 20 years of production lathe experience, main CNC lathe, CNC milling machine, processing center, Swiss CNC lathe high-tech enterprise.The company has a professional production and development team and favorable after-sales technical team support.The company takes the strength to make the product, the service wins the customer, the customer as the basic management concept.Our company has gained a good reputation both at home and abroad by providing customers with cost-effective CNC machine tools and excellent timely sales advice and after-sales service.Development, innovation,people-oriented, is the direction my company has been working on.

Our service

Packing & Delivery

1.Non-fumigation packaging, we use seaworthy plywood.

2. Steel base plate, it is stronger 3-5 times than normal plywood base plate.

3.Water-proof and damp proof, water resistant film wraped all the machine.

4.Fully sheathed case,prevention of collision and keep the goods intact.

2. Steel base plate, it is stronger 3-5 times than normal plywood base plate.

3.Water-proof and damp proof, water resistant film wraped all the machine.

4.Fully sheathed case,prevention of collision and keep the goods intact.

FAQ

How long is your warranty period?

A: our warranty period is one year, and we will maintain the product free of charge during the warranty period.Use our machines to supply standard parts and accessories during shipment.In the correct operation, if there are any damaged parts or accessories,we will replace them immediately by airmail or express mail.

What kind of packing do you have?

Answer: we use a plywood cases, to ensure the packing quality durable, fully protect the safety of the goods in the cabinet,appearance is bright and clean, smooth and beautiful, durable, has low cost, big load, afraid of sun rain no moth, etc.

Big Size QK1327 High Quality CNC Pipe Threading Lathe Machine Pipe Screwing Lathe can be customized?

A: of course, if our product can't meet your need, tell us the model and send us the drawing, recommend suitable products to you,we can also design and produce the machine meet your requirements.

A: of course, if our product can't meet your need, tell us the model and send us the drawing, recommend suitable products to you,we can also design and produce the machine meet your requirements.