Description

Product Description

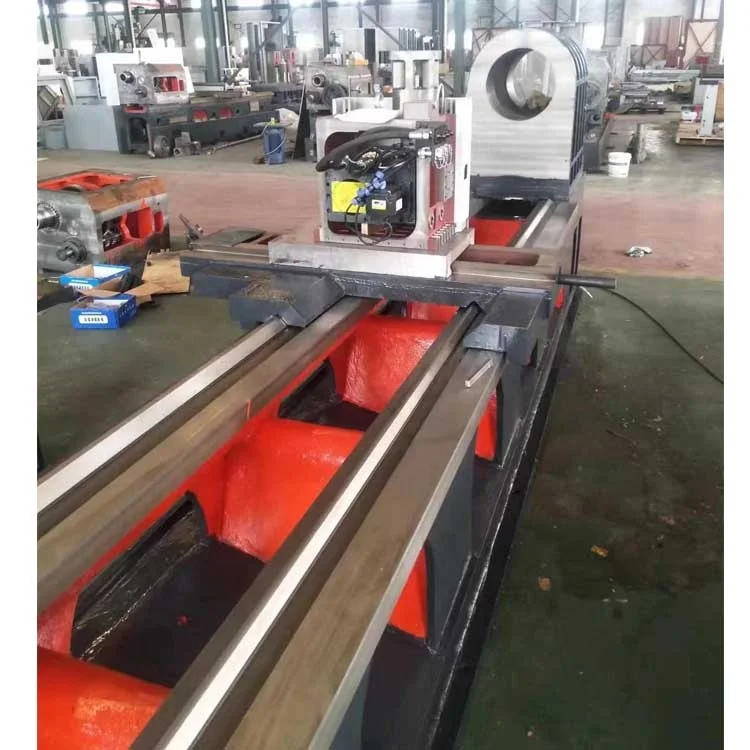

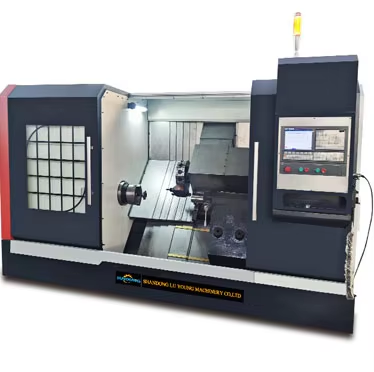

CK61100 heavy metal machine cnc retrofit horizontal lathe

Feature of this ck61100 cnc lathe machine:

1.Max. swing over bed (mm):1000

2.Max. swing dia. over cross slide(mm):630mm

3.Max.processing length(mm):1000/1500/2000/3000

4.chuck: 630 3jaw or 800 4 jaw

5.Diameter of spindle bore (mm):105

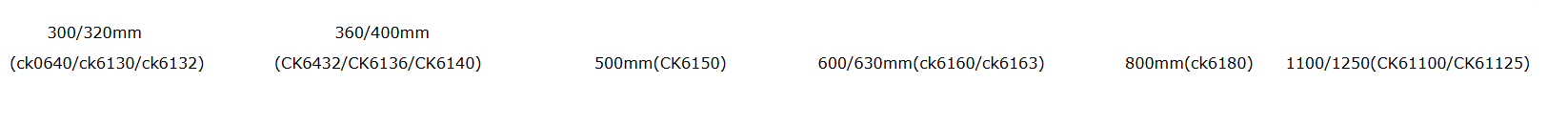

Choose our machine by turning diameter

Choose Our cnc lathe machine by function:

| Item | CK61100 | ||

| Max. swing over bed | mm | Φ1000 | |

| Max. swing dia. over cross slide(mm) | Φ630 | ||

| Processing | Max.processing length | mm | 1000/1500/2000/3000 |

| Max.processing diameter | mm | Φ1000 | |

| maximum diameter of bar | mm | Φ630 | |

| chuck | 630 3jaw or 800 4 jaw | ||

| The spindle terminal structure | D11 | ||

| Spindle | Diameter of spindle bore | mm | Φ105 |

| The taper of spindle front-end | 1:20 | ||

| Spindle speeds series | Four files manually/Hydraulic four files | ||

| Spindle speeds | r/min | 30-84/53-150/125-350/300-835 | |

| X/Z axis travel | mm | 350/(1000/1500/2000/3000) | |

| Feed | X/Z axis lead screw diameter × pitch | mm | φ3208/φ5010 |

| X/Z fast moving | m/min | 4/6 | |

| Tool | Tool post form | Electric vertical | |

| number of work position | 4 | ||

| Tool bar section(turning/boring) | mm | 32/40 | |

| Sleeve diameter / stroke | mm | Φ100/250 | |

| Tailstock | Sleeve inside the hole taper | MT6 | |

| Sleeve driven form | manual | ||

| Tailstock body movement form | Manual | ||

| main motor | Kw | 11 | |

| Spindle motor torque | NM | 48 | |

| Motor of Z axis X | Kw | 1.5/2.3 | |

| Motor | X/Z Nm | NM | 10/15 |

| Coolant motor power | W | 125 | |

| power capacity | KVA | 15 | |

| Bed saddle layout | Flat bed | ||

| Other | Guide form | Harden guide way(> HRC50) | |

| Machine weight | kg | 4300/4700/5500/6500 | |

| length × width × height | mm | ( 3400/3900/4400/5400 )/1900/2000 | |

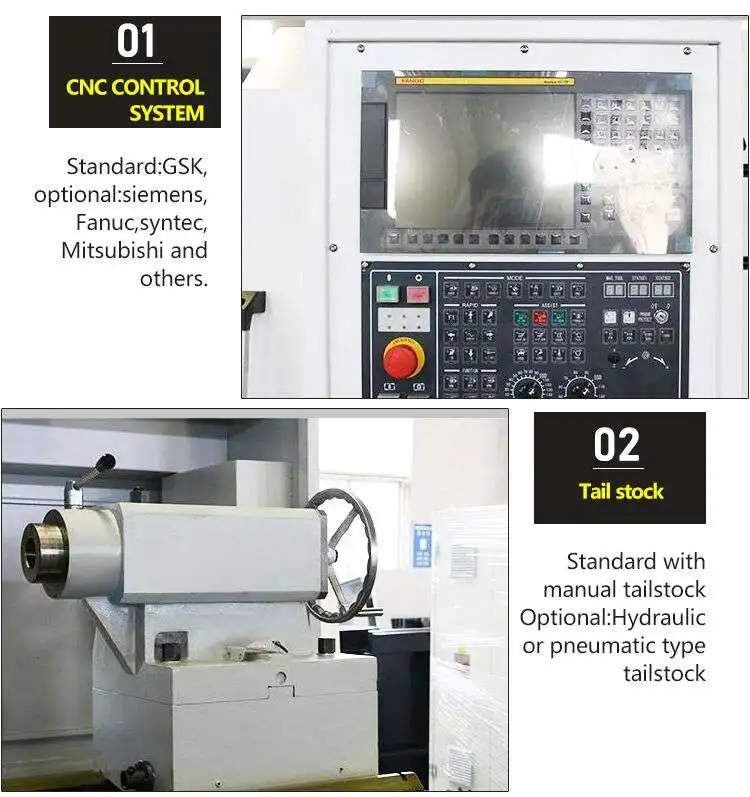

| Standard configuration: | Optional configuration | ||

| GSK980 TB3 controller system | Siemens/Fanuc controller system | ||

| 3 jaw manual chuck | hydraulic hollow chuck | ||

| 4 electric tool holder | pneumatic tailstock/hydraulic tailstock | ||

| Auto lubrication system | 6 /8 station electricl or hydraulic tool turret | ||

| power distribution cabinet | Chip conveyor outside machine | ||

| One-piece bed casting | centre rest | ||

| Manual tailstock | follow-rest | ||

| lighting system | Hydraulic station | ||

| cooling system | |||

Product Feature

Our company

Shandong Lu Young Machinery Co, Ltd. is established in July 1996.We are located in shandong provice.We are one of professional cnc lathe machine, cnc milling machine and swiss lathe machine manufacturer in china.We founded our fast lathe machine factory in 1996 in tengzhou City to produce center lathe and univesal milling machine for over 20 years development,we build three factories.One is for cnc lathe production one for cnc milling production.

We imported advanced production technology and R&D team from Korean in 2001 and build our third factory for swiss lathe machine production.We own about 500 wokers and 40 engineers, more than 5000 square meter .

We imported advanced production technology and R&D team from Korean in 2001 and build our third factory for swiss lathe machine production.We own about 500 wokers and 40 engineers, more than 5000 square meter .

Our engineer team have rich experiences for equipment selection and process design,we can give you professional solution based your workpieces fast and freely.We could product over 1000 sets cnc machine equipment one year. Our cnc machine tools has been exported over 40 countries and get good feedback.

♥ More than 20 years of production experience.♥Exported more than 40 countries.

♥ More than 300 staffs in factory.

♥ CE and ISO9001 certification .

♥ 7×24 hours online service.

Who choose us

The products have exported more than 40 countries around the world and receive many good feedback from our customer, please look who choose us:

FAQ

1.Does the CK61100 heavy metal machine cnc retrofit horizontal lathe can be customized?

Of course, if our standard configuration can not meet your needs, please tell us that we redesign and produce the machine to meet your needs

2.How long is the warranty period of theCK61100 heavy metal machine cnc retrofit horizontal lathe machine?

Warranty period is one year, if parts damage within one year, we will send free of charge. Free online training or factory training to ensure that you can use our products properly. We can offer overseas paid installation, commissioning service.

3.What time is your work time?

We work online 24 hours a day, offer quotes and technical support at any time.

Of course, if our standard configuration can not meet your needs, please tell us that we redesign and produce the machine to meet your needs

2.How long is the warranty period of theCK61100 heavy metal machine cnc retrofit horizontal lathe machine?

Warranty period is one year, if parts damage within one year, we will send free of charge. Free online training or factory training to ensure that you can use our products properly. We can offer overseas paid installation, commissioning service.

3.What time is your work time?

We work online 24 hours a day, offer quotes and technical support at any time.

4.Do you use the Trade Assurance on Alibaba?

Yes, all of the order use this.Can guarantee the quality of the product and your payment.

Yes, all of the order use this.Can guarantee the quality of the product and your payment.

5.How to get a quote?

Please tell us the model you need or send us drawings of the workpiece, then we can recommend the most suitable products to you. We will give you the best offer within 24 hours.

Please tell us the model you need or send us drawings of the workpiece, then we can recommend the most suitable products to you. We will give you the best offer within 24 hours.

6.How to contact with you?

My mobile/whatsapp: +86 18660853235; QQ:3494630853 ;Please send message to us, thanks in advance!

My mobile/whatsapp: +86 18660853235; QQ:3494630853 ;Please send message to us, thanks in advance!