Description

Product Description

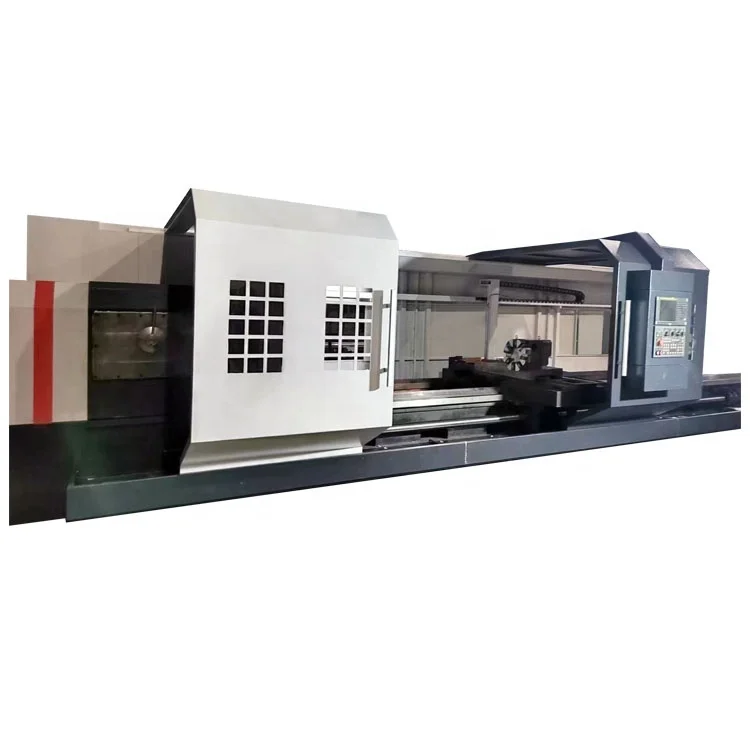

Cnc Lathe Machine CNC Turning Lathe Big Size Chuck CK61125 Powerful CNC Lathe FANUC, high-efficiency automated machine tools, the whole machine with integrated protection structure, beautiful

appearance. Mainly used for complex shape parts or high precision parts processing, can automatically complete internal and external Round surface, conical cotton, round face, end face, a variety of threads, drilling, hinge, boring and other turning. The machine is tested in strict accordance with the inspection procedure. Each machine adopts laser interferometer to detect X and Z axis positioning accuracy and repeat positioning accuracy to ensure the accuracy and reliability of the machine.

appearance. Mainly used for complex shape parts or high precision parts processing, can automatically complete internal and external Round surface, conical cotton, round face, end face, a variety of threads, drilling, hinge, boring and other turning. The machine is tested in strict accordance with the inspection procedure. Each machine adopts laser interferometer to detect X and Z axis positioning accuracy and repeat positioning accuracy to ensure the accuracy and reliability of the machine.

Cnc Lathe Machine CNC Turning Lathe Big Size Chuck CK61125 Powerful CNC Lathe FANUC

Specification

| Item | CK61125*1500 | CK61125*2000 | CK61125*3000 |

| Max. swing over bed (mm) | Φ1250 | Φ1250 | Φ1250 |

| Max. swing dia. over cross slide(mm) | Φ970 | Φ970 | Φ970 |

| Max.processing length(mm) | 1500 | 2000 | 3000 |

| Form | Three gears No grade to change frequency | ||

| Number of spindle speed | No grade | ||

| Range of spindle speed(r/min) | 6-500 rpm | ||

| The spindle terminal structure | C11 | ||

| Diameter of spindle bore (mm) | φ130 | ||

| The taper of spindle front-end | (Metric)120 1:20 | ||

| Power of main motor (KW) | 15KW | ||

| Max.travel of tool post (mm) | X:530 Z:1700/X:530 Z:2300/X:530 Z:3300 | ||

| Fast moving feed speed (mm/min) | X:4000 Z:5000 | ||

| Resetting accuracy(mm) | X:0.012 Z:0.016 | ||

| Processing accuracy(mm) | IT6-IT7 | ||

| Surface roughness | Ra1.6 | ||

| Sleeve diameter of tailstock (mm) | φ100 | ||

| Sleeve travel of tailstock (mm) | 250 | ||

| Cone hole taper of tailstock’ sleeve | MT6 | ||

| Standard configuration | Four-station vertical electrical knife rest | ||

| Restting accuracy (mm) | 0.01 | ||

| Length of section of knife handle (mm) | 30×30 | 30×30 | 30×30 |

| Length*width*height | 3700×1920×1990 | 4700×1920×1990 | 5700×1920×1990 |

| Net weight (Kg) | 6500 | 8000 | 9000 |

Products feature

Standard Configuration :

-

♥- System:GSK980. X/Z axis servo motor.

-

♥- Manual 3-jaw chuck.

-

♥- 4-station electric tool post.

-

♥- Manual tailstock

-

♥- Cooling system.

-

♥- Lighten system.

- ♥- Automatic lubrication system.

Optional Configuration:

-

♦- CNC system: Siemens, Fanuc, KND.

-

♦- Hydraulic chuck/Pneumatic chuck.

-

♦- Hydraulic tailstock/Pneumatic tailstock.

-

♦- Horizontal 6-station turret/8-station turret.

-

♦- Auto bar feeder

- ♦- Chip conveyor

Quality Inspection Process

Company Profile

Luyang CNC machinery company has 20 years of production lathe experience, main CNC lathe, CNC milling machine, processing center,Swiss CNC lathe high-tech enterprise.The company has a professional production and development team and favorable after-sales technical team support.The company takes the strength to make the product, the service wins the customer, the customer as the basic management concept.Our company has gained a good reputation both at home and abroad by providing customers withcost-effective CNC machine tools and excellent timely sales advice and after-sales service.Development, innovation,people-oriented, is the direction my company has been working on.

Packing & Delivery

Our packing is standard sea export plywood box, which can guarantee the quality of the goods and also reduce the loss.The mode of transportation is by sea.

You can also pack and transport according to your requirements

You can also pack and transport according to your requirements

Customer Photos

-

1. Our customers come from more than 40 different countries and promote the most suitable products for different countries to provide the best service;

- 2 we participated in many exhibitions, the Chinese machinery exhibition, guangzhou commodities fair, through the exhibition to expand overseas market, we invite customers to visit our factory, also can be customized according to customer demand, through ourproducts and services for customers

our services

1. We supply 24 hours on-line service,you could contact with us by email ,phone ,wechat ,whatsapp,skype etc.

2. Received your phone or mail,we will Analyze the problem immediately.

3.Supply professional solution, after analyze the problem, we give you our best solution.

4. The warranty period of the whole machine is 1 year. Under normal use, if the machine parts are damaged during the warranty period, we will provide free accessories. Outside the warranty period, if the parts are damaged, we only charge the cost price of the parts, and will never overcharge.

5. Provide lifetime free technical support, you can contact us at any time if you encounter difficulties in the process of use.

6. We provide overseas services, engineers can go to the customer's factory for debugging,installation, maintenance, and repair. (In case of non-epidemic situation).

Certifications

FAQ

Warranty period is how long?

A: Our warranty period is one year, during the warranty period we will repair the product for free. Standard parts and accessoriesare supplied when shipped using our machines. In the correct operation, if there is any damaged parts or accessories, we willimmediately use air mail or courier instead.

What kind of packaging?

A: We use plywood boxes to ensure the packaging quality durable, fully protect the safety of the cabinet, the appearance of brightand clean, smooth and beautiful, durable, low cost, heavy load, fear of the sun and rain without moths and so on.

Delivery date is how long?

Our delivery date is one month. 30 days

Does the Cnc Lathe Machine CNC Turning Lathe Big Size Chuck CK61125 Powerful CNC Lathe FANUC can be customized?

Of course, if our standard configuration can not meet your needs, please tell us that we redesign and produce the machine to meetyour needs

How to contact you?

my email:[email protected].