Description

Product Overview

A pipe thread lathe is a specialized machine tool designed for processing internal and external threads on pipe fittings. It has various features and applications.

FEATURES AT A GLANCE

Main Features

1. High Processing Efficiency: * Capable of machining straight and tapered pipe threads, suitable for pipe joints, casing, and other types of pipes, meeting the needs of industries such as oil, geology, mining, and chemical engineering.

2. Large Diameter Machining: * The processing diameter can reach up to 190 mm, making it suitable for turning large-diameter pipe fittings.

3. Multi-functionality: * In addition to thread machining, this lathe can also perform standard lathe functions such as external turning, internal boring, and end-face machining, enhancing its versatility.

4. Automation and Precision: * Modern CNC pipe thread lathes are equipped with servo motors and high-rigidity composite bearing

structures to ensure accurate positioning and stable transmission, thereby improving machining precision.

5. Simplified Operation: * The lathe design allows for cutting both metric and imperial threads without changing gears,simplifying the operational process.

6. Wear Resistance and Stability: * The bed guideways are treated with quenching to enhance wear resistance, while the design

considers vibration reduction and stability to improve machining quality.

7. Easy Clamping of Long Workpieces: * The front and rear double chuck structure design provides more secure clamping for long

pipes, increasing processing efficiency.

8. Ease of Maintenance and Operation: * The lathe is equipped with automatic protection devices that ensure it can stop automatically in case of anomalies, protecting both the machine tool and the workpiece.

Left elevation

Front elevation

Right elevation

PRODUCT SPECIFICATIONS

| SPECIFICATIONS | Units | Q1319 | Q1322 |

| Swing over bed | mm | 630/800 | 630/800 |

| Swing over cross slide | mm | 340/520 | 340/520 |

| Distance between centers | mm | 1500/3000 | 1500/3000 |

| Pipe threading range | mm | 50-193 | 50-220 |

| Guideway width | mm | 550 | 550 |

| Max. load capacity | kg | 3000 | 3000 |

| Spindle bore | mm | 200 | 230 |

| Spindle speed steps | - | /VF. 4 steps | /VF. 4 steps |

| Spindle speed range | rpm | 20-550 | 20-550 |

| Chuck | mm | φ520/4-jaw manual | φ520/4-jaw manual |

| Turret/tool post | - | /Manual 4 position | /Manual 4 position |

| Tool shank size | mm | 32 x 32 | 32 x 32 |

| X axis travel | mm | 320/420 | 320/420 |

| Z axis travel | mm | 1350/2850 | 1350/2850 |

| X axis feed steps/range | mm/r | 22/0.02-0.45 | 22/0.02-0.45 |

| Z axis feed steps/range | mm/r | 26/0.07-1.33 | 26/0.07-1.33 |

| X axis rapid traverse | mm/min | 2300 | 2300 |

| Z axis rapid traverse | mm/min | 4000 | 4000 |

| Metric thread kinds /range | mm | 1-15 | 1-15 |

| Inch thread kinds /range | T.P.I | 1-14 | 1-14 |

| Tailstock quill diameter | mm | 100 | 100 |

| Tailstock quill taper | - | MT5 | MT5 |

| Tailstock quill travel | mm | 250 | 250 |

| Main spindle motor | kw | 11 | 11 |

| Rapid traverse motor | kw | 0.3 | 0.3 |

| Coolant pump motor | kw | 0.125 | 0.125 |

| Weight for 1500 | kg | 4300 | 4500 |

| Weight for 3000 | kg | 5500 | 5700 |

| Dimension for 1500 | mm | 3700x1550x1550 | 3700x1650x1550 |

| Dimension for 3000 | mm | 5200x1550x1550 | 5200x1650x1550 |

PRODUCT CONFIGURATION

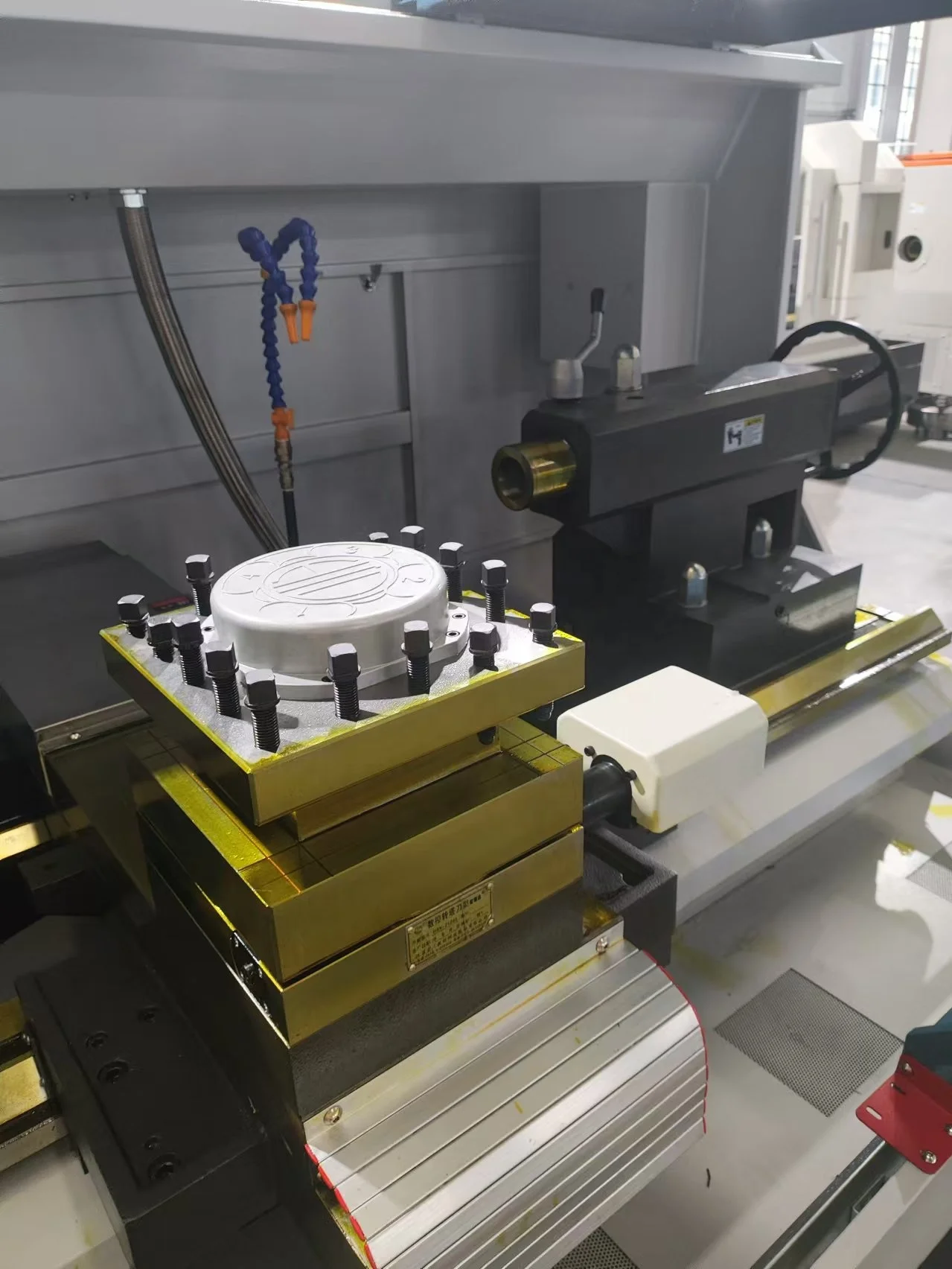

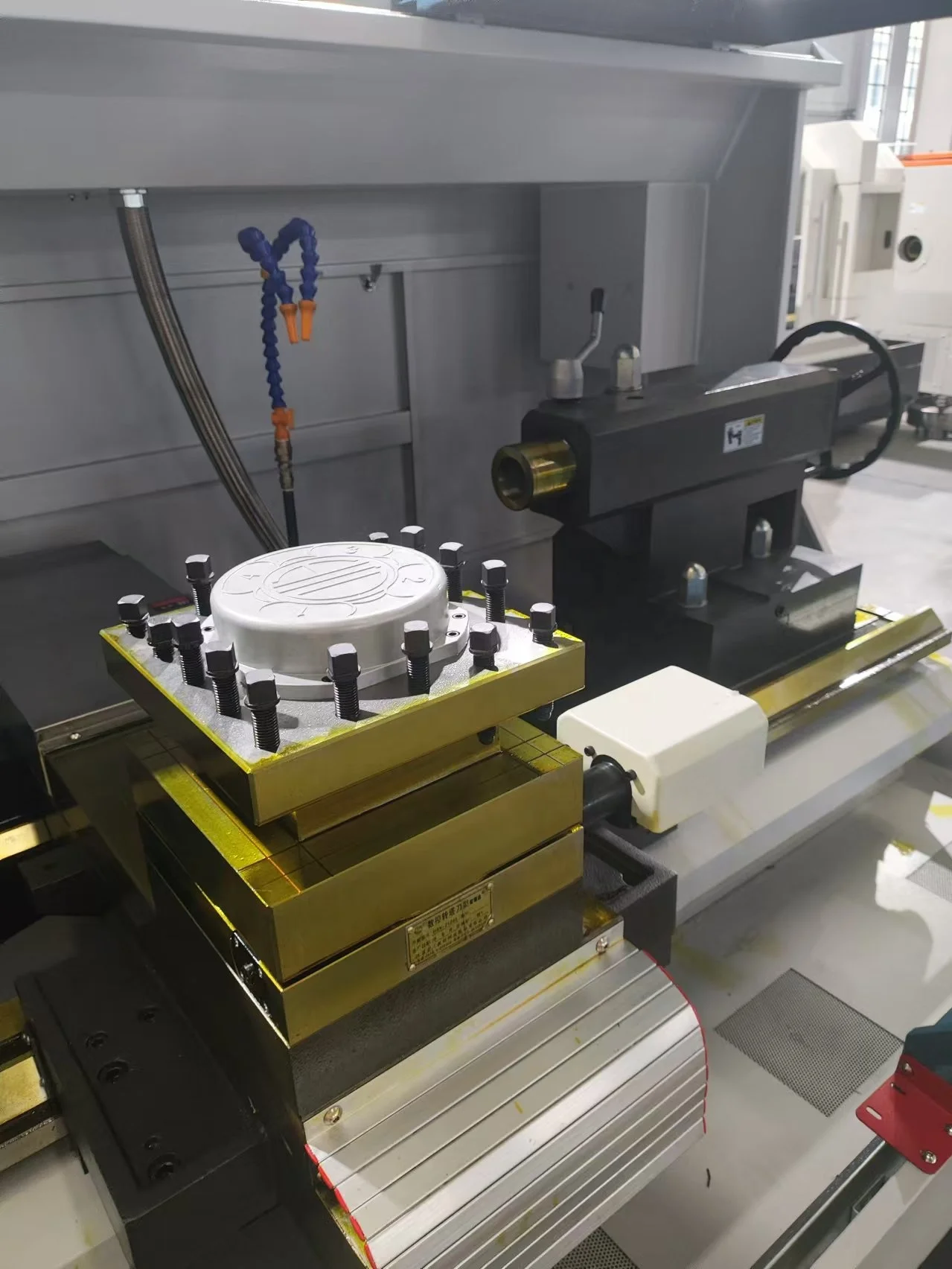

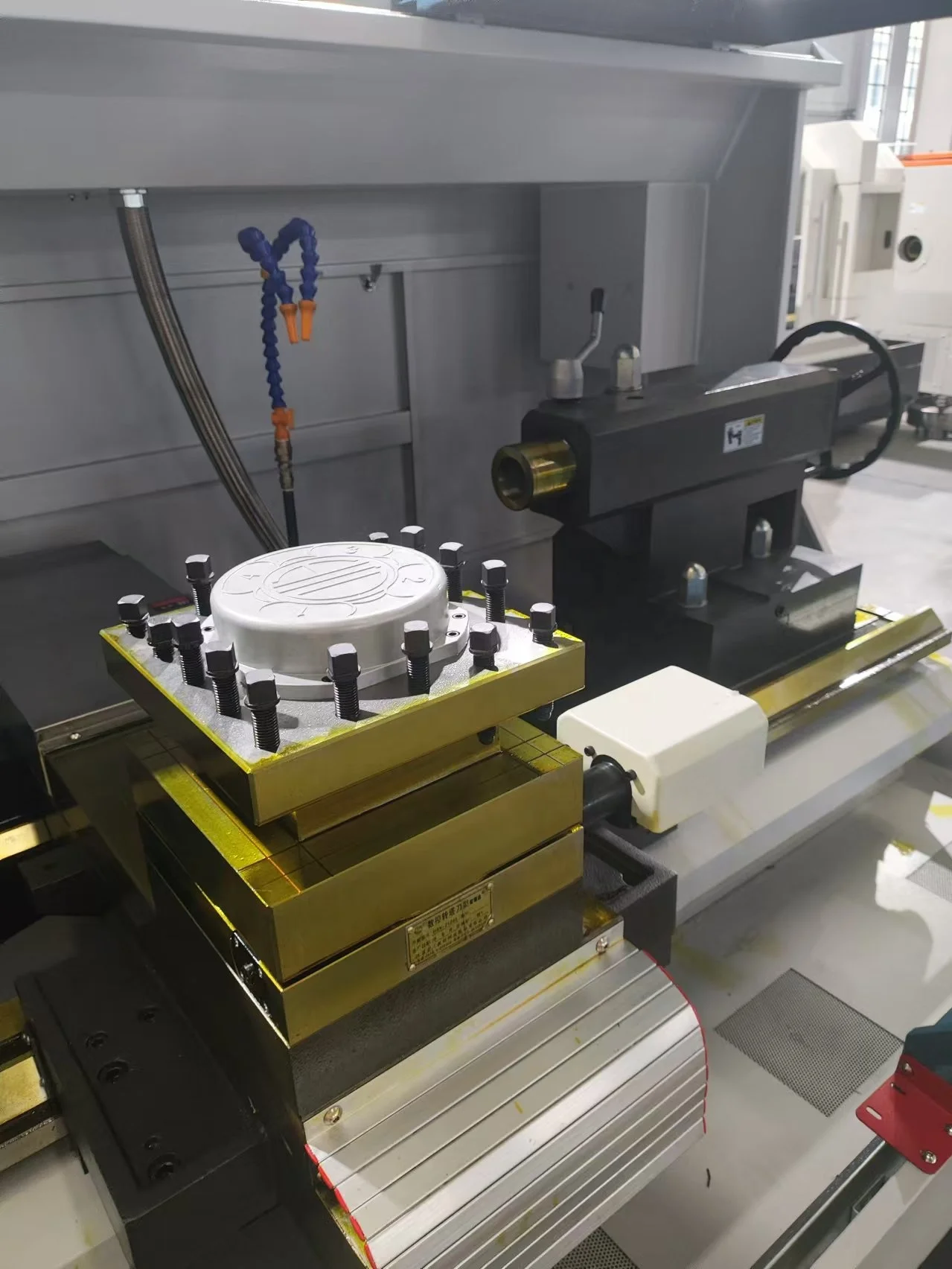

Chuck

4 station electrical tool holder

Manual tailstock

SALES AND SERVICE NETWORK

Successful Project

Project in China

Project in Indionsia

Project in Brazil

SIMILAR PRODUCTS

FAQ

Q1:Introduction about shipping and after-sale services

A1:1.Port: Qingdao port or Shanghai port

2.Payment method: T/T, L/C, D/P, D/D etc.

3.Payment: 30% T/T as deposit, 70% balance shall be paid before shipment.

4.Delivery time: 30 days after receive the 30%T/T deposit.

2.Payment method: T/T, L/C, D/P, D/D etc.

3.Payment: 30% T/T as deposit, 70% balance shall be paid before shipment.

4.Delivery time: 30 days after receive the 30%T/T deposit.

5.Non-fumigation packaging, we use seaworthy plywood.

6. Steel base plate, it is stronger 3-5 times than normal plywood base plate.

7.Water-proof and damp proof, water resistant film wraped all the machine.

8.Fully sheathed case,prevention of collision and keep the goods intact.

6. Steel base plate, it is stronger 3-5 times than normal plywood base plate.

7.Water-proof and damp proof, water resistant film wraped all the machine.

8.Fully sheathed case,prevention of collision and keep the goods intact.