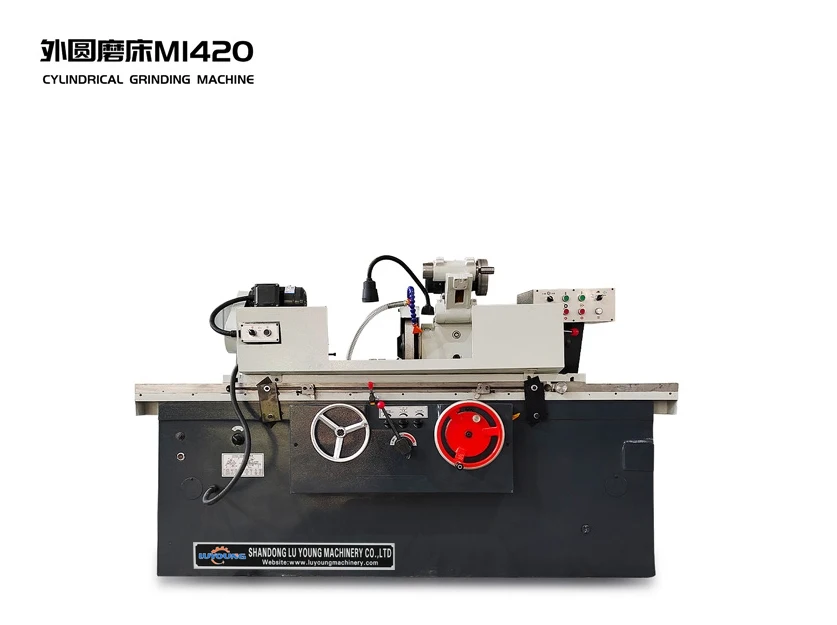

High Precision Tool Cutter Grinding Machine M7163x1250 Universal Tool Cutter Sharpener Grinder Machine

Description

Product Overview

High Precision Tool Cutter Grinding Machine M7163x1250 Universal Tool Cutter Sharpener Grinder Machine

A surface grinding machine is a type of machine tool used for grinding the plane or end face of a work piece, and it has thefollowing characteristics:

I. High machining accuracy High - precision grinding capability

The spindle of the grinding head of a surface grinding machine is highly precise. The spindle is usually supported by a high

precision bearing system, which can ensure the stability of the spindle during high - speed rotation. For example, the radial

run out of the spindle of a precision surface grinding machine can be controlled at the micron level. Some high - end precision grinding machine spindles can achieve a radial run out of 0.001 mm or even higher precision. This allows the grinding wheel to remove material very precisely during the grinding process, thereby obtaining a high - precision plane.

The movement accuracy of the worktable is also very important. The linear motion guide of the worktable is precision - machined and assembled, which can ensure that the work piece moves smoothly along the predetermined trajectory during the grinding process. Its movement accuracy can generally reach 0.002 - 0.005 mm/1000 mm travel range, which helps to ensure the flatness and dimensional accuracy of the work piece plane.

I. High machining accuracy High - precision grinding capability

The spindle of the grinding head of a surface grinding machine is highly precise. The spindle is usually supported by a high

precision bearing system, which can ensure the stability of the spindle during high - speed rotation. For example, the radial

run out of the spindle of a precision surface grinding machine can be controlled at the micron level. Some high - end precision grinding machine spindles can achieve a radial run out of 0.001 mm or even higher precision. This allows the grinding wheel to remove material very precisely during the grinding process, thereby obtaining a high - precision plane.

The movement accuracy of the worktable is also very important. The linear motion guide of the worktable is precision - machined and assembled, which can ensure that the work piece moves smoothly along the predetermined trajectory during the grinding process. Its movement accuracy can generally reach 0.002 - 0.005 mm/1000 mm travel range, which helps to ensure the flatness and dimensional accuracy of the work piece plane.

PRODUCT SPECIFICATIONS

| Worktable | Size(Length x Width) | mm | 1250x630 | |

| Max grinding size (Length x Width) | mm | 1250x630 | ||

| Longitudinal movement of the workbench (hydraulic drive) | mm | 200-1350 | ||

| T-slot quantity x width(mm) | mm | 3x18 | ||

| Longitudinal velocity(stepless) | m/min | 5-28 | ||

| Workbench load capacity (including electronic suction cup) | Kg | 980 | ||

| Dimensions of the electronic suction cup (width × length) | mm | 630×1250 | ||

| Grinding head | The stroke of grinding head Honzrional | mm | 630 | |

| Transverse feed of the grinding head (stepless speed regulation) | mm/min | 0.8-3 | ||

| Continuous | mm/次 | 5-25 | ||

| Intermittent | ||||

| Minimum graduation of the vertical hand wheel | mm | 0.01 | ||

| Vertical feed per revolution of the hand wheel | ||||

| Grinding wheel dimensions (Outer Diameter × Width × Inner Diameter) | mm | Φ400×50×Φ203 | ||

| Total motor power | kw | 15 | ||

| Grinding head motor | power | kw | 7.5 | |

| Speed | r/min | 1440 | ||

| Accuracy | The machine surface of the base of parallelism | mm | 0.02/300 | |

| Surface roughness | u.m | Ra0.63 | ||

| Weight | Net weight/gross weight | kg | 5500/6200 | |

| Machine size(LxWxH) | mm | 3800× 2100×2500 | ||

PRODUCT CONFIGURATION

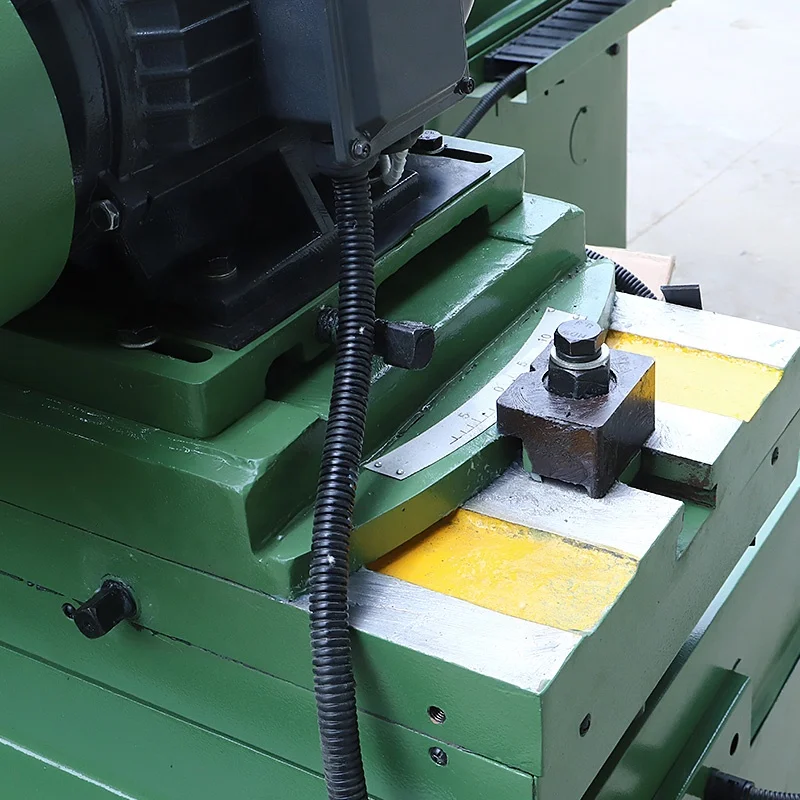

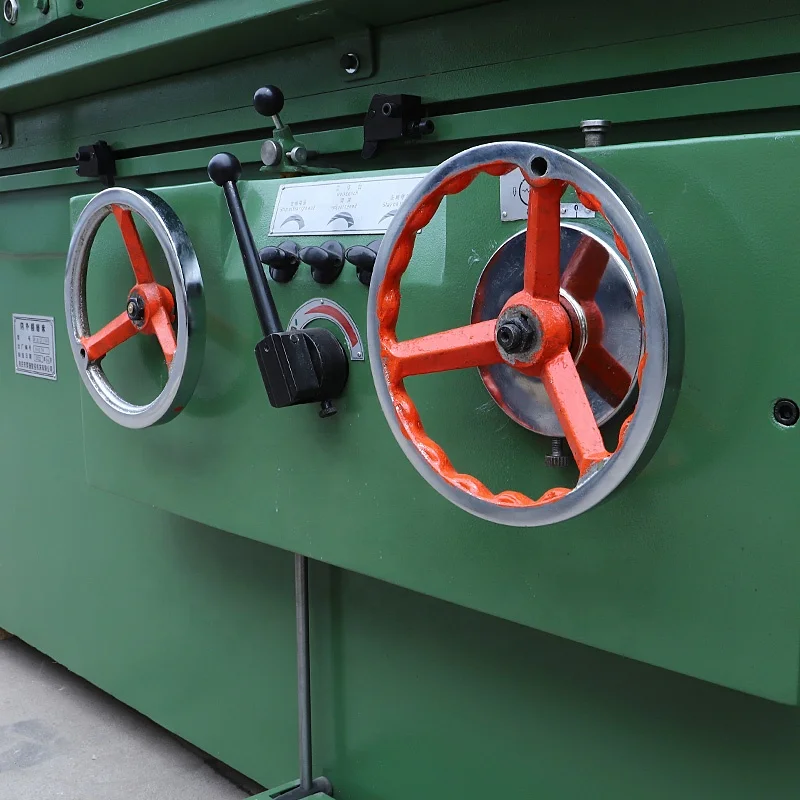

Side

SALES AND SERVICE NETWORK

Successful Project

Project in China

Project in China

SIMILAR PRODUCTS

FAQ

Q:How long is the warranty time of High Precision Tool Cutter Grinding Machine M7163x1250 Universal Tool Cutter Sharpener Grinder Machine?

A:One year for whole machine