Description

Product Description

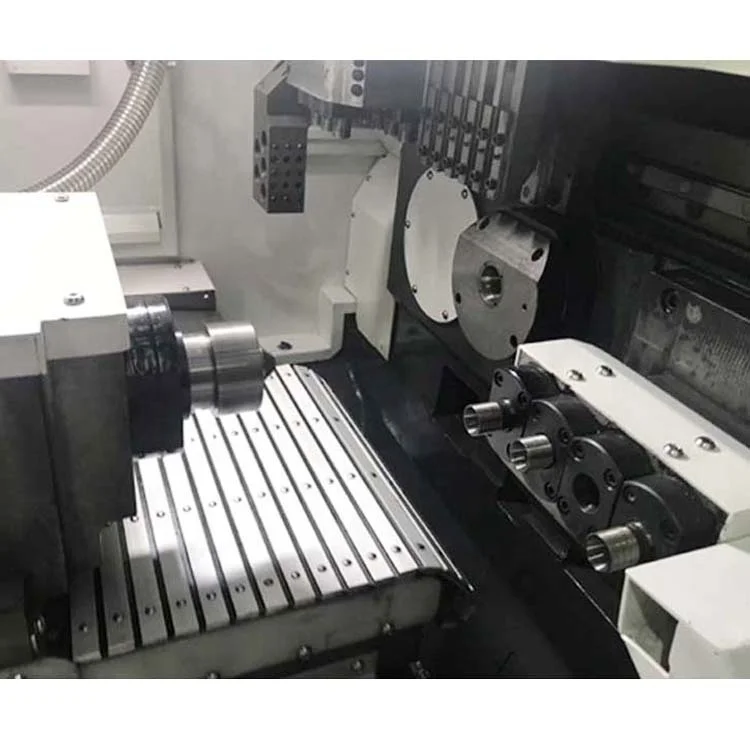

SM385 Swiss type flat bed cnc lathe Double Spindle Swiss Cnc Lathe Machine

1. High-speed, high-precision, and high-efficiency: The optimal tool layout adopts high-speed arithmetic processing control to minimize the tool change time and obtain the best positioning at the same time, reducing the auxiliary time to the shortest.

2. High configuration: Concentrating the most advantageous functional components, multi-axis abundant tool configuration, and standard power tools, which greatly expands the processing range and meets the complex processing of complex parts.

3. Convenient operation processing space: Convenient operation space, easy to change the tool, vertical downward tool can obtain the best chip removal.

2. High configuration: Concentrating the most advantageous functional components, multi-axis abundant tool configuration, and standard power tools, which greatly expands the processing range and meets the complex processing of complex parts.

3. Convenient operation processing space: Convenient operation space, easy to change the tool, vertical downward tool can obtain the best chip removal.

SM385 Swiss type flat bed cnc lathe Double Spindle Swiss Cnc Lathe Machine

Specification

| describe | unit | specifications | |||

| Processing capacity | Max maching diameter | mm | ¢38 | ||

| Stroke | mm | 210 | |||

| Main Spindle RPM | rpm | 8000 | |||

| Sub Spindle RPM | rpm | 8000 | |||

| Cross Driven Tools RPM | rpm | 5000 | |||

| Main/Sub Spindle CS axis indexing minimum unit | ° | 1/1000(0.001) | |||

| Rapid Traverse Rate | X1 /Z1axis | m/min | 24 | ||

| Y/X2/Z2 axis | m/min | 32 | |||

| Arrangement of tools | O.D Tools | ea | 5 | ||

| Front Work Tools | ea | 5 | |||

| Cross Driven Tools | ea | 4 | |||

| Back Work Tools | ea | 4(fixed) | |||

| O.D Tools specification | mm | □16×16 | |||

| Front Work Tools diameter | mm | 3¢25+2¢20 | |||

| three¢25+tow¢20 | |||||

| Power Tool Chuck Specifications | mm | ER16 | |||

| Motors | Spindle motor | kw | 5.5/7.5 | ||

| Sub Spindle motor | kw | 1.5/2.2 | |||

| Servo axis motor | kw | 0.75 | |||

| Cross Driven Tools motor | kw | 0.55/1.1 | |||

| Lubrication pump motor | w | 100 | |||

| Coolant motor | kw | 0.9 | |||

| Others | Coolant tank capacity | L | 200 | ||

| Lubrication tank capacity | L | 1.8 | |||

| Height from floor tospindle center | mm | 1000 | |||

| Floor space | (L) | mm | 2760 | ||

| (W) | mm | 1564 | |||

| (H) | mm | 1882 | |||

| Mass of machine | kg | 4500 | |||

| CNC control unit | set | FANUC oi TF PLUS | |||

| 1 | CNC controller: FANUC Controller system |

| 2 | Automatic lubrication system |

| 3 | Water pump cooling system |

| 4 | Full Protection Frame |

| 5 | Cross living tools,4live tools |

| 6 | Z axis direction Fixed cutter holder,4 drilling tools holder(ER16) |

| 7 | P4 classes Precision screw guide:Japan THK brand(X、Y、Z) |

| 8 | Electric spindle |

| 9 | Bearing:Japan NSK |

| 10 | C axis Stepless indexing |

| 11 | X1、Y1、Z1、Z2 、X2 aixs servo motor: Japan YASGAWA |

| 12 | Driving---Japan YASGAWA |

| 13 | Long workpieces feed tube |

Product Feature

What is the feature ofSM385 Swiss type flat bed cnc lathe Double Spindle Swiss Cnc Lathe Machine

♥ Powerful whirlwind milling processing capability: For bone screws, lead screws, worms, and screw parts, high-precision spiral grooves need to be processed, and the surface roughness of the spiral grooves needs to reach Ra0.8μm.The thread processing method of the machine tool with high motion accuracy and good dynamic stability is required.

♥ High rigidity turning and milling combined processing capabilities:

Used in communication, home appliances, electronics, toys and other industries with large diameter parts and components, theprocess is complicated, the precision is high, and the combined processing of turning and milling is required, and the amount of cutting tools is large. SX325 CNC core walking machine powerful turning and milling processing can be One-cut processing to size.

Application

The use requirements of SM385 Swiss type flat bed cnc lathe Double Spindle Swiss Cnc Lathe Machine

1. Products that require mass processing are suitable for automatic lathe processing. Trouble.

2. When using an automatic lathe for processing, the workpiece structure should be suitable for automatic sorting of the workpiece and suitable for automatic feeding.

3. Whether the material of the workpiece is suitable for automatic processing. Generally, brass, zinc alloy, ordinary carbon steel and other materials have better processing performance and less wear on tools, so they are more suitable for automatic lathe processing.

4. Whether the diameter, length, and processing technology of the workpiece are suitable for automatic lathe processing.

Company Profile

Luyang CNC machinery company has 20 years of production lathe experience, main CNC lathe, CNC milling machine, processing center,Swiss CNC lathe high-tech enterprise.The company has a professional production and development team and favorable after-sales technical team support.The company takes the strength to make the product, the service wins the customer, the customer as the basic management concept.Our company has gained a good reputation both at home and abroad by providing customers with cost-effective CNC machine tools and excellent timely sales advice and after-sales service.Development, innovation,people-oriented, is the direction my company has been working on.Our company continuously strengthen product performance improvements, innovation cost-effective CNC machinery, optimize product quality control system, to provide global support services as the dominant direction of the development of the company.

Packing & Delivery

1.Non-fumigation packaging, we use seaworthy plywood.

2. Steel base plate, it is stronger 3-5 times than normal plywood base plate.

3.Water-proof and damp proof, water resistant film wraped all the machine.

4.Fully sheathed case,prevention of collision and keep the goods intact.

2. Steel base plate, it is stronger 3-5 times than normal plywood base plate.

3.Water-proof and damp proof, water resistant film wraped all the machine.

4.Fully sheathed case,prevention of collision and keep the goods intact.

Certifications

FAQ

1. How can I get a quotation?

A. Leave us massage with your purchase requements and we will reply you ASAP. And you may contact us directly by Trade Manager or Telephone.

2. Can you provide customized machine or SPM (Special purpose machine)?

A. Yes, we provide smart CNC solutions for our customer, in order to increase efficiency.

3. Can you provide training for operation CNC machines?

A. Yes, free training in our factory is available.

4. How about your price?

A. Send me details about what you need, you will get the best price in China. The price is competitive over the world.

5. What’s the delivery time, and what’s the package?

A. Normally the delivery time is about 30-45 days. All our CNC machines are packed with sea worthy package.