VMC1580 CNC Milling Machine Center 5 Axis Fanuc Control System Vertical Machining Center

Description

Product Description

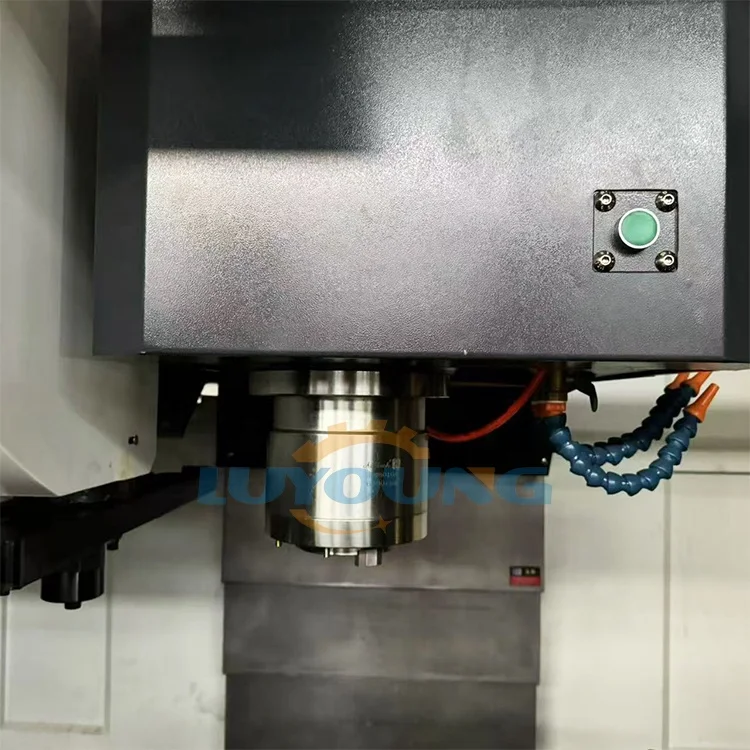

The VMC1580 CNC Milling Machine Center 5 Axis Fanuc Control System Vertical Machining Center Main Functions of CNC Vertical Machining Center CNC vertical machining center use popular inverted T-shape column structure, it is morden machine tool with automatic tool changer and 3/4-axis CNC system. Continous & automatic milling, drilling, expanding, hinges and tapping on 4 surfaces' machining processes after once clamped, suitable for medium batch process all kinds of flat surface, hole, complicated surfaces machining. Saving processes, shorten production cycle, improved processing accuracy, it is the ideal machining equipment for automobile; construction mechanical;

VMC1580 CNC Milling Machine Center 5 Axis Fanuc Control System Vertical Machining Center

Specification

| Item | VMC1580 CNC Milling Machine Center 5 Axis Fanuc Control System Vertical Machining Center |

| Size of worktable(length× width)mm | 1700*800 |

| T slot (mm) | 5-22x150 |

| Max loading weight on worktable | 1500 |

| X-Axis travel(mm) | 1500 |

| Y-Axis travel(mm) | 800 |

| Z-Axis travel(mm) | 700 |

| Distance between spindle nose and table | 170-840 |

| Distance between spindle | 810 |

| center and column(mm) | |

| Spindle taper | BT50-155 |

| Max. spindle speed( rpm) | 8000/10000/12000 |

| Spindle motor power(Kw) | 18.5kw |

| Rapid feeding speed: X,Y,Z axis m/min | 16/16/16 (24/24//24 liner guidway) |

| Fast cutting speed m /min | 10m/min |

| Positional accuracy | ±0.01 mm |

| Repeat positional accuracy | ±0.005mm |

| Auto Tool changer type | 16 tools head type tool changer(optional 24 arm type auto tool changer) |

| Max. tool length | 300mm |

| Max. Tool diameter | Φ80(adjacent tool)/φ150(not adjacent tool) |

| Max.tool weight | 8kg |

| Tool changing time(tool-to-tool) | 7sec |

| Air pressure | 0.6 Mpa |

| Machine weight | 13000KG |

VMC850/VMC855

Table size:1000*500(mm)vmc850

Travel of 3 axis(x.y.z)

1000*500*500(mm)

Table size:1000*550(mm)vmc855

Travel of 3 axis(x.y.z) 1000*500*500(mm)

1000*500*500(mm)

Table size:1000*550(mm)vmc855

Travel of 3 axis(x.y.z) 1000*500*500(mm)

VMC1060/VMC1160

vmc1060

Table size:1300*600(mm)Travel of 3 axis(x.y.z)

1000*600*600(mm)

vmc1160 Table size:1300*600(mm)

Travel of 3 axis(x.y.z) 1100*600*600(mm)

Table size:1300*600(mm)Travel of 3 axis(x.y.z)

1000*600*600(mm)

vmc1160 Table size:1300*600(mm)

Travel of 3 axis(x.y.z) 1100*600*600(mm)

VMC1270/VMC1370

Table size:1200*600(mm)Travel of 3 axis(x.y.z)

1000*600*600(mm)

vmc1370 Table size:1300*600(mm)

Travel of 3 axis(x.y.z) 1100*600*600(mm)

Table size:1200*600(mm)Travel of 3 axis(x.y.z)

1000*600*600(mm)

vmc1370 Table size:1300*600(mm)

Travel of 3 axis(x.y.z) 1100*600*600(mm)

Products feature

Main Features of VMC1580 CNC Milling Machine Center 5 Axis Fanuc Control System Vertical Machining Center

1. Rigid base with integral structure adopted

2. Good durability with cast iron machine bed made through super audio quenching

3. Good dynamic performance with advanced guide rail laminating technology

4. High precision, high-rigidity spindle, high speed

5. Sufficient precise lubrication with automatic lubrication system

6. Row knife structure which can change knifes very fast, high positioning accuracy and simple maintenance

7. Wide range of machining products due to the travel distance of X direction is up to 270mm and variety of knife tools can be installed on the machine tool

8. Spring chuck with high accuracy and high efficiency

9. Good protection function with fully-closed safe glass window 10. Modular design and optional accessories available on customer's needs

Company Profile

Company specializing in CNC machinery research and development in 20 years, we have good technology, and advanced team, to provide efficient service, for the ball more than 40 countries research and development, production, sales of the company.CNC lathe, CNC milling machine, machining center Our company has independently developed a series has established a large number of special machine tools for many enterprises, whose products are reliable.Price discount, deeply loved by new and old customers.High-quality finished products, perfect pre-sales and after-sales service, is our company's quality purpose, is the pursuit of all employees of our company, is also the guarantee of the majority of users' trust.

Packing & Delivery

Our packing is standard sea export plywood box, which can guarantee the quality of the goods and also reduce the loss.

The mode of transportation is by sea.

You can also pack and transport according to your requirements

The mode of transportation is by sea.

You can also pack and transport according to your requirements

Our Services

1. The warranty period of our products is one year. If there is any damage in the warranty period, we will send it to you for free.We provide 24-hour online technical service and contact us at any time.

2. 365 days without false service, uninterrupted supply, pre-sales consultation, after-sales service and other technical support We also offer free technical training and overseas services.

2. 365 days without false service, uninterrupted supply, pre-sales consultation, after-sales service and other technical support We also offer free technical training and overseas services.

Exhibition

1. Our customers come from more than 40 different countries and promote the most suitable products for different countries to provide the best service;

2 we participated in many exhibitions, the Chinese machinery exhibition, guangzhou commodities fair, through the exhibition to expand overseas market, we invite customers to visit our factory, also can be customized according to customer demand, through our products and services for customers

2 we participated in many exhibitions, the Chinese machinery exhibition, guangzhou commodities fair, through the exhibition to expand overseas market, we invite customers to visit our factory, also can be customized according to customer demand, through our products and services for customers

FAQ

Warranty period is how long?

A: Our warranty period is one year, during the warranty period we will repair the product for free. Standard parts and accessoriesare supplied when shipped using our machines. In the correct operation, if there is any damaged parts or accessories, we willimmediately use air mail or courier instead.

What kind of packaging?

A: We use plywood boxes to ensure the packaging quality durable, fully protect the safety of the cabinet, the appearance of brightand clean, smooth and beautiful, durable, low cost, heavy load, fear of the sun and rain without moths and so on.

Delivery date is how long?

Our delivery date is one month. 30 days

Does VMC1580 CNC Milling Machine Provided cnc Machine Model 400 for Metals Vertical 3 Axis 12 Motor New Product Single Customizedcan be customized?

Of course, if our standard configuration can not meet your needs, please tell us that we redesign and produce the machine to meetyour needs

What kind of packaging?

A: We use plywood boxes to ensure the packaging quality durable, fully protect the safety of the cabinet, the appearance of brightand clean, smooth and beautiful, durable, low cost, heavy load, fear of the sun and rain without moths and so on.

Delivery date is how long?

Our delivery date is one month. 30 days

Does VMC1580 CNC Milling Machine Provided cnc Machine Model 400 for Metals Vertical 3 Axis 12 Motor New Product Single Customizedcan be customized?

Of course, if our standard configuration can not meet your needs, please tell us that we redesign and produce the machine to meetyour needs