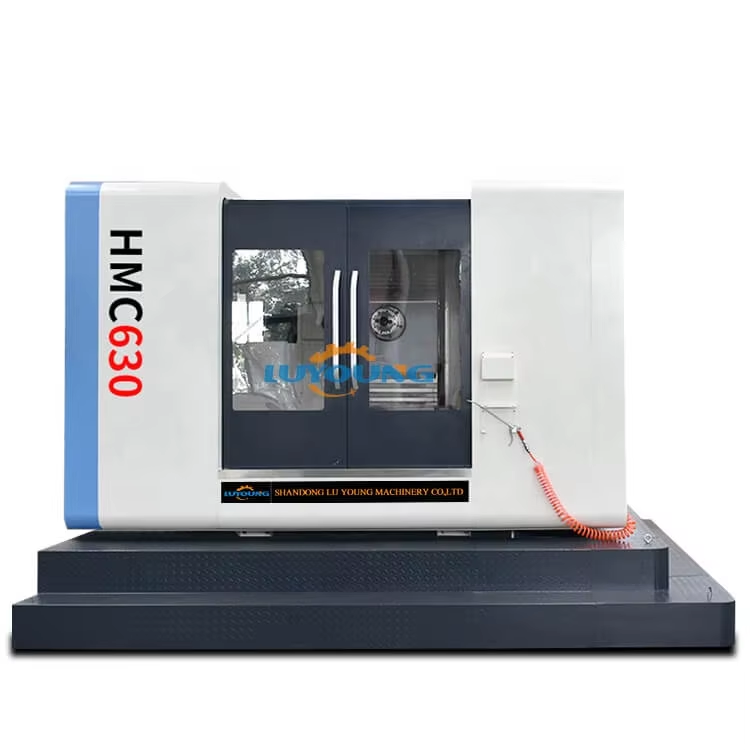

Our horizontal machining centers stand out in the global market due to their advanced engineering and robust design. With a focus on precision and efficiency, these machines are equipped with cutting-edge technology that enhances their operational capabilities. Designed for high-volume production, our horizontal machining centers can handle a variety of materials, ensuring that they meet the rigorous demands of modern manufacturing.

The horizontal layout of our machining centers allows for easier chip removal and better coolant flow, which is crucial for maintaining tool life and ensuring machining accuracy. Additionally, the large work envelopes provide the flexibility needed for complex workpieces, making them suitable for both small and large-scale production runs.

Our commitment to quality is evident in every machine we produce. By utilizing advanced materials and manufacturing processes, we ensure that our horizontal machining centers not only meet but exceed industry standards. Our machines have been successfully exported to over 40 countries, receiving positive feedback for their reliability and performance. Whether you are looking to enhance your existing operations or invest in new machinery, our horizontal machining centers are the best choice for achieving your production goals.