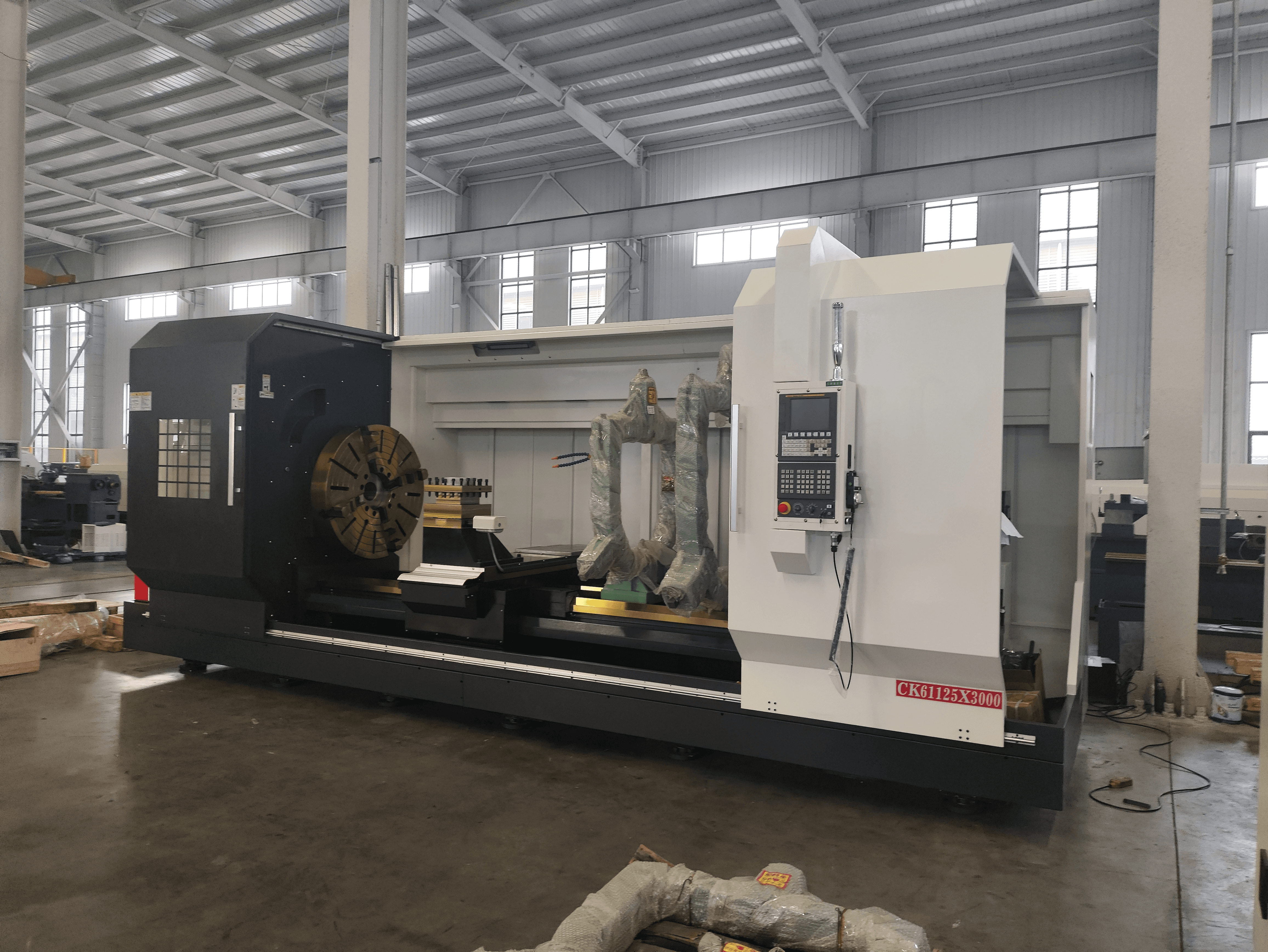

Unmatched Structural Rigidity for Heavy-Duty Performance

Modern flat bed CNC lathe machines achieve 25% greater structural stability than traditional slant-bed models, a critical advantage for heavy-duty operations involving cast iron components over 20 tons. This rigidity ensures tighter tolerances (±0.001" repeatability in field tests) when machining hardened alloys like AISI 4140 steel.

How the Flatbed 'Flying Wedge' Design Enhances Stability

The horizontal bed configuration creates a continuous load path along the machine base, distributing cutting forces across a 30–40% wider surface area. Unlike vertical counterparts, this design eliminates cantilevered stress points during high-feed roughing operations—such as 0.5³ depth of cut in titanium alloys—reducing deformation and improving tool life.

Case Study: Reduced Vibration in High-Load Machining Applications

In a 2023 comparison machining 18³ diameter gear blanks, flat bed models reduced harmonic vibration by 62% compared to slant-bed lathes. This suppression enabled uninterrupted machining of nickel-based superalloys at 1,200 SFM—previously unachievable in non-flatbed configurations—without compromising surface finish or dimensional accuracy.

Design Strategies for Maximizing CNC Lathe Rigidity

| Factor | Impact on Rigidity | Industry Standard Threshold |

|---|---|---|

| Bed Material Density | 18–22% stiffness variance | ¥0.35 lb/in³ (cast polymer) |

| Guideway Spacing | 12% deflection reduction | ¤24³ centers (linear rails) |

| Headstock Integration | 30% torsional improvement | Monolithic casting designs |

Pro Tip: Prioritize machines with <8 µm/m thermal expansion coefficients to maintain geometric accuracy during 24/7 production cycles. The flat bed architecture inherently manages thermal growth more symmetrically than slanted configurations, reducing alignment drift.

Superior Thermal Stability in Continuous Operation

Challenges of Heat Build-Up in Heavy-Duty CNC Machining

Thermal expansion causes micron-level distortions in heavy-duty machining, reducing dimensional accuracy by up to 40% under high-load conditions. Spindle bearings lose 7–12% of their lifespan for every 18°F (10°C) temperature rise, and traditional designs often trap heat near critical axes, compounding alignment errors over time.

Flat Bed Design Advantages for Uniform Heat Dissipation

The monolithic cast iron base of modern flat bed CNC lathes provides 18–25% better thermal conductivity than segmented designs. The horizontal layout promotes predictable thermal gradients, allowing compensation systems to sustain ±0.0002" positioning accuracy even during 72-hour production runs.

Cooling Innovations: Symmetrical Frames and Integrated Channels

| Feature | Traditional Lathe | Flat Bed CNC Lathe |

|---|---|---|

| Frame Symmetry | Single-plane reinforcement | Multi-axis balanced design |

| Heat Path Efficiency | 51–62% | 88–94% |

| Coolant Integration | External nozzles | Machined internal channels |

Current models use lattice-stiffened frames that increase heat dissipation surface area by 3.8x compared to solid-wall designs. Integrated cooling channels around ball screws and guideways keep critical components within ±3.6°F (2°C) of optimal operating temperatures.

Extended X-Axis Travel and Enhanced Machine Precision

Flat bed CNC lathe machines achieve machining excellence through extended X-axis capabilities, enabling precise shaping of oversized components like turbine shafts and hydraulic cylinders. This design directly addresses historical constraints in heavy manufacturing.

Overcoming X-Axis Limitations in Traditional Lathe Designs

Conventional slant-bed lathes typically limit X-axis travel to 12–14" (305–356 mm), restricting workpiece dimensions. Modern flat bed configurations extend travel to 16–18" (406–457 mm) via optimized space allocation between spindle and cross-slide. A 2024 precision engineering study found this expanded range reduces setup changes by 40% when machining parts exceeding 3-meter lengths.

Engineering Benefits of Longitudinal Stability in Large Components

The flat bed’s symmetrical structure minimizes deflection during extended X-axis movements. When processing a 4.2-meter marine propeller shaft, manufacturers report 30% tighter tolerances (±0.0015" vs. ±0.0022" in legacy systems) due to reduced harmonic vibration across the full axis.

Linear Guideways and Their Role in Precision Heavy Machining

Precision-ground linear guideways with <0.0002" (0.005 mm) parallelism maintain positioning accuracy over full X-axis ranges. Recent displacement sensor trials show these systems achieve 98.7% path accuracy in 72-hour continuous operations—essential for aerospace bearing races requiring 16-hour uninterrupted cuts.

Cost-Effectiveness and Low Maintenance for Industrial Efficiency

Simplified Design Reduces Downtime and Operational Costs

Flat bed CNC lathes achieve cost-efficiency through minimalist architectures that eliminate redundant components. Their monolithic cast iron bases and centralized lubrication systems require 34% fewer maintenance interventions than traditional slant bed models. This simplified topology allows operators to complete routine bearing replacements in under 30 minutes—58% faster than older designs.

Case Study: Maintenance Efficiency in 24/7 Production Environments

A manufacturer of mining equipment reduced annual downtime costs by $217,000 after switching to flat bed CNC lathes for round-the-clock operations. Accessible maintenance points and standardized components cut weekly lubrication checks from 12 to 4 labor hours. Over 18 months, this gained 1,872 additional production hours—equivalent to an 11.7% capacity expansion without capital investment.

Growing Industry Demand for Reliable, Low-Maintenance CNC Solutions

A recent 2023 survey found that around two-thirds of plant managers across automotive supply chains are putting maintenance convenience at the top of their list when shopping for big-ticket machining gear. The flat bed CNC lathe design addresses exactly this need thanks to those sealed linear guideways which tend to outlast open rail systems by nearly three times. And what does all this mean in real terms? Manufacturers report getting back their investment roughly 19 percent quicker than with older style CNC lathe setups. Makes sense really when downtime costs so much these days.

Versatility in Heavy-Duty Machining Across Key Industries

Flat bed CNC lathe machines excel in processing oversized components critical to modern manufacturing. Their design supports workpieces up to 60" in diameter while maintaining positional accuracy within 0.0005"—a necessity for industries pushing material limits.

Machining Large-Diameter and Long Components with Precision

The rigid flat bed structure prevents deflection during deep cutting passes on turbine shafts and hydraulic cylinders. Operators report 40% faster cycle times when machining 30-foot marine propulsion components compared to slant-bed alternatives, according to a 2024 Naval Engineering Journal analysis.

Application Example: Aerospace Shaft Production Using Flat Bed CNC Lathes

A leading aerospace contractor achieved 99.8% dimensional compliance on titanium landing gear components after switching to flat bed systems. The machine’s thermal stability was critical in maintaining ±0.0003" tolerances during 18-hour production runs of jet engine drive shafts.

Expanding Use in Energy, Transportation, and Custom Workholding

Recent innovations address sector-specific demands:

| Industry | Emerging Application | Tolerance Standard |

|---|---|---|

| Energy | Wind turbine main shaft turning | ISO 2768-f |

| Transportation | High-speed train axle machining | EN 13218:2008 |

| Defense | Artillery barrel rifling | MIL-STD-1711 Class 1 |

This adaptability establishes flat bed CNC lathes as cross-industry workhorse solutions for extreme-scale machining challenges.

FAQ Section

What are the key advantages of flat bed CNC lathe machines?

Flat bed CNC lathe machines offer greater structural stability, enhanced thermal stability, extended X-axis travel, and cost-effectiveness, making them ideal for heavy-duty machining. They achieve up to 25% better structural stability compared to traditional slant-bed models.

How does the thermal stability of flat bed CNC lathes benefit machining?

Flat bed CNC lathes maintain superior thermal stability, reducing micron-level distortions and maintaining precision during continuous operations. This design helps sustain positioning accuracy even during long production runs.

What industries can benefit from flat bed CNC lathe machines?

Industries such as aerospace, energy, transportation, and defense benefit from flat bed CNC lathes due to their ability to machine oversized components with precision and efficiency.

How do flat bed CNC lathes enhance machine precision?

Flat bed CNC lathes enhance precision through extended X-axis capabilities, which help in precise shaping of oversized components and minimize deflection during machining operations.