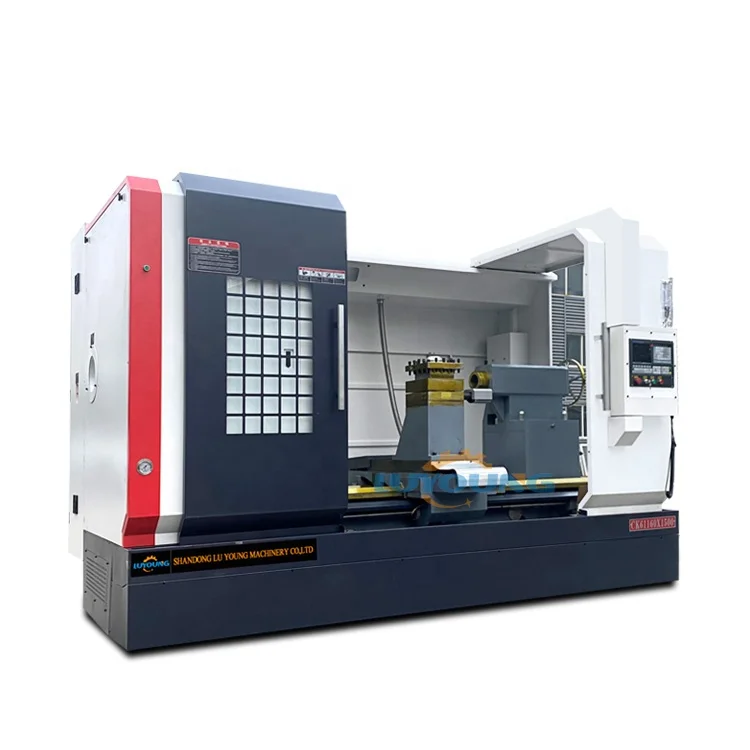

China Manufacturer Cheap Horizontal GSK Controller System CK61140 Metal CNC Machine Heavy Duty Cnc Turning Lathe Machine

Description

Specification

China Manufacturer Cheap Horizontal GSK Controller System CK61140 Metal CNC Machine Heavy Duty Cnc Turning Lathe Machine. This machine tool is suitable for processing various complex-shaped shafts, sleeves, and disk parts, such as turning inner and outer cylindrical surfaces, conical surfaces, arc surfaces, end faces, grooving, chamfering, threading, etc. It is especially suitable for multi-variety, small and medium-sized Batch processing in turns, strong process adaptability, high processing efficiency, low scrap rate, good consistency of finishedproducts, easy programming and simple operation, it is an ideal large-scale mechanical processing equipment.

China Manufacturer Cheap Horizontal GSK Controller System CK61140 Metal CNC Machine Heavy Duty Cnc Turning Lathe Machine

hot-selling product

| Item | Unit | CK61140 |

| Max. swing over bed | mm | 1400 |

| Max. swing dia. over cross slide | mm | 1000 |

| Width of bed guide rail | mm | 755 |

| Distance between 2 centers | mm | 1500/ 2000/ 3000/ 5000/ 6000/ 8000 |

| Max. truning length | mm | 1300/1800/2800 4800/5800/7800 |

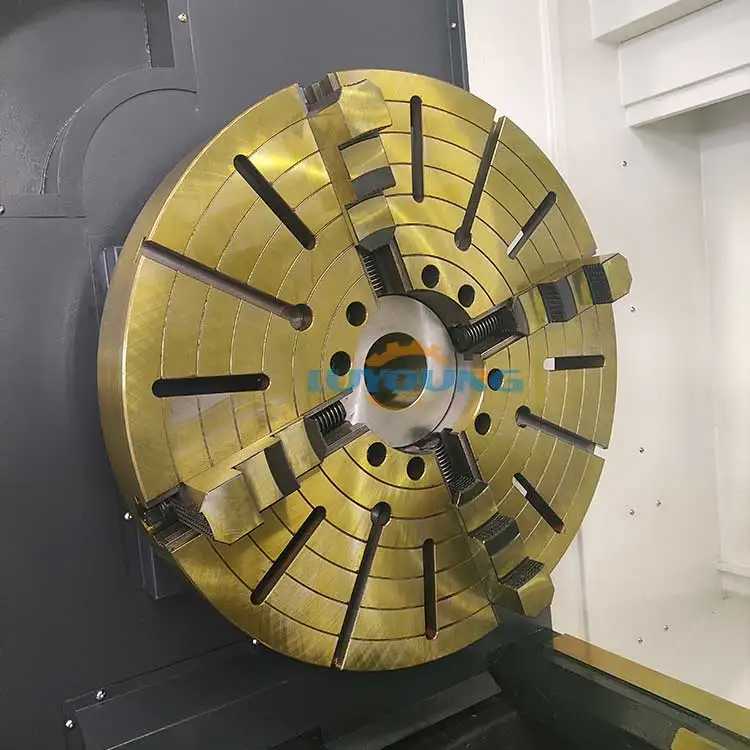

| Chuck diameter | mm | Φ1000 ;4 jaw ;manual |

| Spindle type | A2-15 | |

| spindle bore | mm | 130mm |

| Taper of spindle | mm | 1:20/140 |

| Main shaft gears | Manual gear change | |

| Spindle speed range | r/min | 4-470; Fourth speed gear |

| Height of spindle center from bed | mm | 800 |

| Minimum X/Z feed increment | mm | 0.001/0.001 |

| Main power | KW | 22 |

| X/Z axis Fast moving speed | m/min | 3/6 |

| X/Z axis travel | mm | 750/2000 |

| Accuracy of workpiece | IT6-IT7 | |

| Workpiece surface roughness | µm | Ra1.6 |

| Tool post | 4 station electric tool post | |

| Tool holder rotation time | s | 2.6 |

| Repositioning accuracy of tool holder transposition | mm | 0.01 |

| Tool size | mm | □45×45 |

| Diameter of tailstock quill | mm | 160 |

| Tail seat sleeve diameter/stroke | mm | 300 |

| Taper of tailstock | / | Morse 6 |

| Machine weight | 9000kG | |

| X axis | Positioning accuracy (mm) | 0.03 | ||

| repeated positioning accuracy(mm) | 0.012 | |||

| Z axis | Positioning accuracy(mm) | 1500 | 3000 | 5000 |

| 0.045 | 0.06 | 0.08 | ||

| repeated positioning accuracy(mm) | 0.02 | 0.025 | 0.025 | |

Standard Configuration :Cheap Horizontal GSK Controller System CK61140 Metal CNC Machine Heavy Duty Cnc Turning Lathe Machine

- System:GSK980. X/Z axis servo motor.

- Manual 3-jaw chuck.

- 4-station electric tool post.

- Manual tailstock

- Cooling system.

- Lighten system.

- Automatic lubrication system.

Optional Configuration: Cheap Horizontal GSK Controller System CK61140 Metal CNC Machine Heavy Duty Cnc Turning Lathe Machine

- CNC system: Siemens, Fanuc, KND.

- Hydraulic chuck/Pneumatic chuck.

- Hydraulic tailstock/Pneumatic tailstock.

- Horizontal 6-station turret/8-station turret.

- Auto bar feeder

- Chip conveyor

Product Feature

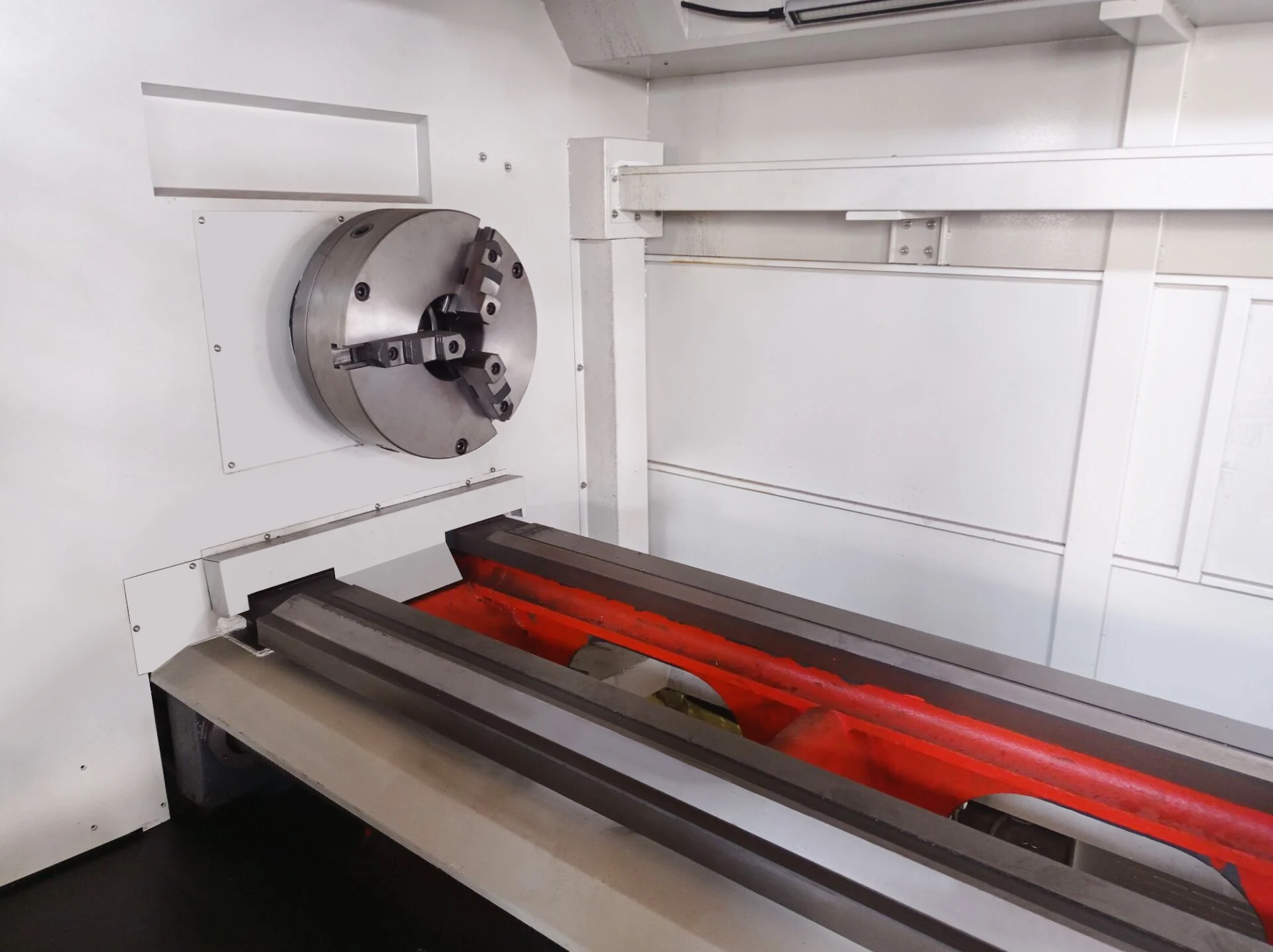

Spindle

45#steel forged spindle,High speed, high precision, strong rigidity;The spindle speed change adopts manual four-speed speed change and stepless speed regulation within the gear, which greatly reduces the probability of machine tool operation failure. Mature structure, stable performance, easy programming and simple operation.

Guide rail of the bed

The guide rail of the bed is finely ground after being quenched by the super-audio frequency, with high hardness, good rigidity and long service life. The carriage adopts the plasticization process of the guide rail surface, which has good wear resistance and high precision.

High-strength grey cast iron resin sand mould integral casting.

The casting is tempered twice to eliminate the internal stress of the casting itself.The whole machine is good, the machining accuracy is high, and the stability of the machine tool is guaranteed for long-term use.

Spindle box

The four-speed speed regulation of the main shaft adopts a gear box structure, especially the three-point support of the main shaft of this machine tool, which has the outstanding characteristics of high speed, high precision, strong rigidity, small thermal deformation, stable operation and low noise.

Controller system

The standard is GSK980TB3 controller system, the optional is Siemens ,Fanuc or Syntec controller system. Simple and easy to operate,with the operation manual.

Tailstock

There is a device in the tailstock sleeve to prevent the rotation of the drill bit, which avoids damage to the taper of the inner hole of the tailstock sleeve due to the rotation of the drill bit caused by misoperation, and effectively protects the tailstock components

Chuck

The standard chuck is 3 jaw manual chuck, the optional configuration is 3 jaw or 4 jaw hydraulic hollow chuck.

Turret

The standard turret is 4 station electric turret, the optional is 6/8 station electric turret or 12 station living turret.

Optional configuration of :

Lu Young

Shandong Lu Young Machinery Co, Ltd. is established in July 1996.We are located in shandong provice.We are one of professional cnc lathe machine, cnc milling machine and swiss lathe machine manufacturer in china.We founded our fast lathe machine factory in 1996 in tengzhou City to produce center lathe and univesal milling machine for over 20 years development,we build three factories.One is for cnc lathe production one for cnc milling production.

We imported advanced production technology and R&D team from Korean in 2001 and build our third factory forswiss lathe machine production.We own about 500 wokers and 40 engineers, more than 5000 square meter .

We imported advanced production technology and R&D team from Korean in 2001 and build our third factory forswiss lathe machine production.We own about 500 wokers and 40 engineers, more than 5000 square meter .

Our engineer team have rich experiences for equipmentselection and process design,we can give you professional solution based your workpieces fast and freely.We could product over 1000 sets cnc machine equipment one year. Our cnc machine tools has been exported over 40 countries and get good feedback.

♥ More than 20 years of production experience.♥Exported more than 40 countries.

♥ More than 300 staffs in factory.

♥ CE and ISO9001 certification .

♥ 7×24 hours online service.

Our service

Cheap Horizontal GSK Controller System CK61140 Metal CNC Machine Heavy Duty Cnc Turning Lathe Machine

1. We supply 24 hours on-line service,you could contact with us by email ,phone ,wechat ,whatsapp,skype etc.

2. Received your phone or mail,we will Analyze the problem immediately.

3.Supply professional solution, after analyze the problem, we give you our best solution.

4. The warranty period of the whole machine is 1 year. Under normal use, if the machine parts are damaged during the warranty period, we will provide free accessories. Outside the warranty period, if the parts are damaged, we only charge the cost price of the parts, and will never overcharge.

5. Provide lifetime free technical support, you can contact us at any time if you encounter difficulties in the process of use.

6. We provide overseas services, engineers can go to the customer's factory for debugging,installation, maintenance, and repair. (In case of non-epidemic situation).

Who choose us

The products have exported more than 40 countries around the world and receive many good feedback from our customer, please look who choose us:

Packaging

Cheap Horizontal GSK Controller System CK61140 Metal CNC Machine Heavy Duty Cnc Turning Lathe Machine

1.Port: Qingdao port or Shanghai port

2.Payment method: T/T, L/C, D/P, D/D etc.

3.Payment: 30% T/T as deposit, 70% balance shall be paid before shipment.

4.Delivery time: 30 days after receive the 30%T/T deposit.

5.Non-fumigation packaging, we use seaworthy plywood.

6. Steel base plate, it is stronger 3-5 times than normal plywood base plate.

7.Water-proof and damp proof, water resistant film wraped all the machine.

FAQ

1.Does the Cheap Horizontal GSK Controller System CK61140 Metal CNC Machine Heavy Duty Cnc Turning Lathe Machine can be customized?

Of course, if our standard configuration can not meet your needs, please tell us that we redesign and produce the machine to meet your needs

2.How long is the warranty period of the Cheap Horizontal GSK Controller System CK61140 Metal CNC Machine Heavy Duty Cnc Turning Lathe Machine?

Warranty period is one year, if parts damage within one year, we will send free of charge. Free online training or factorytraining to ensure that you can use our products properly. We can offer overseas paid installation, commissioning service.

3.What time is your work time?

We work online 24 hours a day, offer quotes and technical support at any time.

Of course, if our standard configuration can not meet your needs, please tell us that we redesign and produce the machine to meet your needs

2.How long is the warranty period of the Cheap Horizontal GSK Controller System CK61140 Metal CNC Machine Heavy Duty Cnc Turning Lathe Machine?

Warranty period is one year, if parts damage within one year, we will send free of charge. Free online training or factorytraining to ensure that you can use our products properly. We can offer overseas paid installation, commissioning service.

3.What time is your work time?

We work online 24 hours a day, offer quotes and technical support at any time.

4.Do you use the Trade Assurance on Alibaba?

Yes, all of the order use this.Can guarantee the quality of the product and your payment.

Yes, all of the order use this.Can guarantee the quality of the product and your payment.

5.How to get a quote?

Please tell us the model you need or send us drawings of the workpiece, then we can recommend the most suitable products to you. We will give you the best offer within 24 hours.

Please tell us the model you need or send us drawings of the workpiece, then we can recommend the most suitable products to you. We will give you the best offer within 24 hours.

6.How to contact with you?

My mobile/whatsapp: +86 18660853235; QQ:3494630853 ;Please send message to us, thanks in advance!

My mobile/whatsapp: +86 18660853235; QQ:3494630853 ;Please send message to us, thanks in advance!