Description

Specification

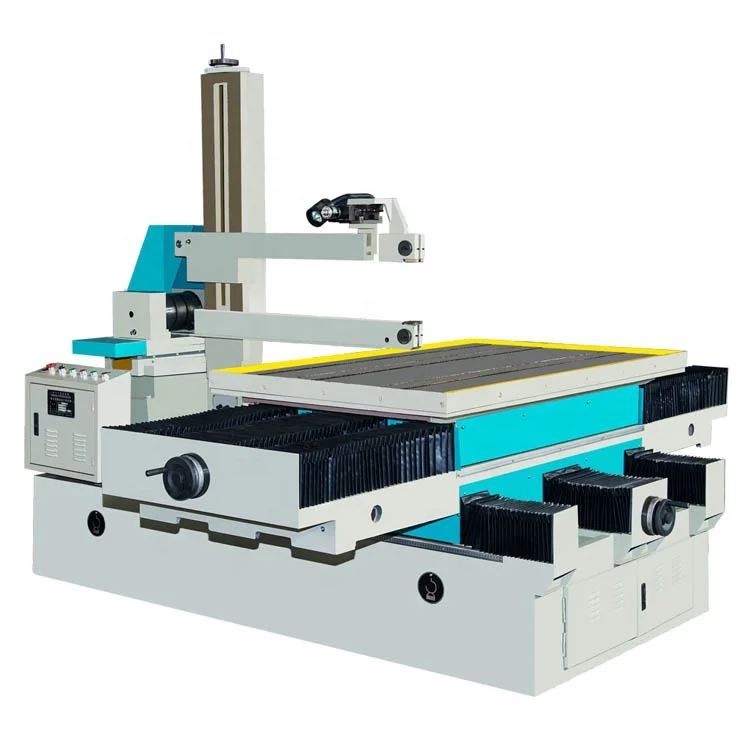

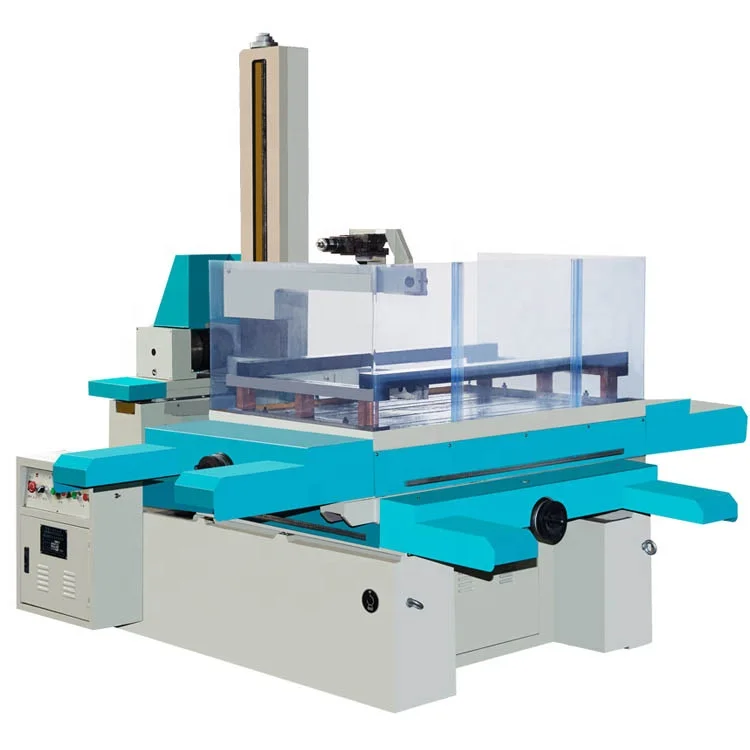

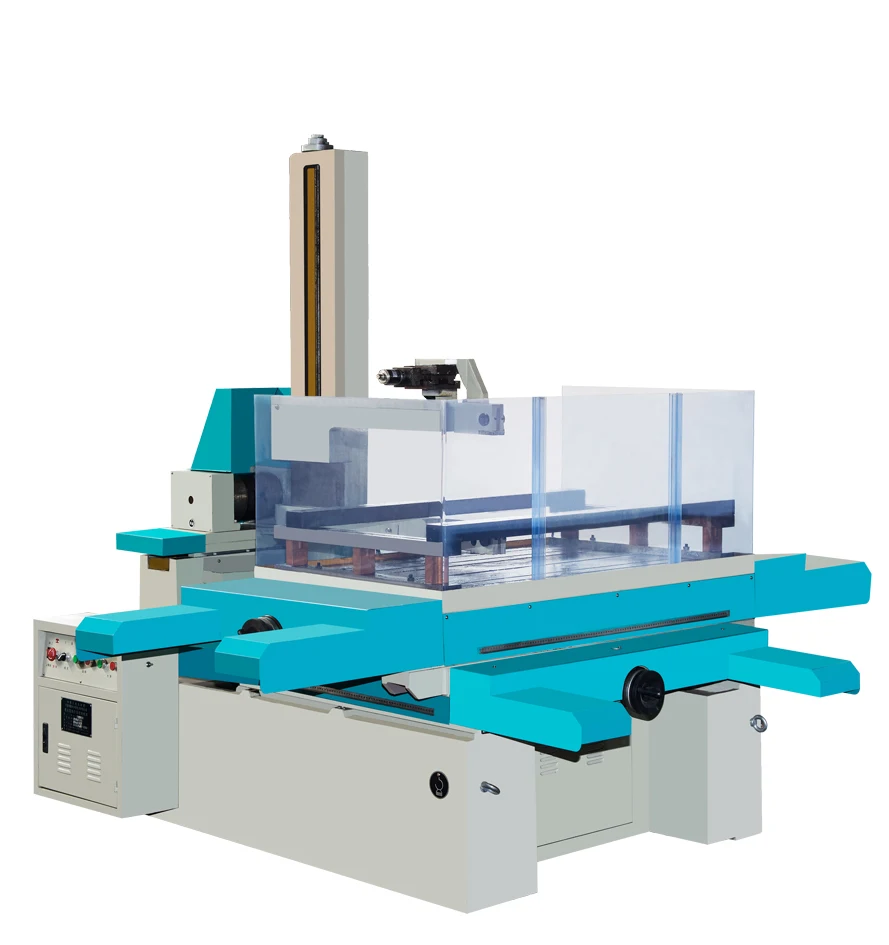

DK7745 high speed cutting 3/4/5 axis wire edm machine cnc edm machine wire cutting

Table travel: 450 × 550 mm

Linear cutting thickness: 400 mm

Processing taper: ±3°

Molybdenum wire linear range: 0.15-0.22

Optimal roughness: ≤Ra2.5

Processing accuracy: According to national standards

Machine tool maximum load: 450kg

Maximum processing efficiency: not less than 160mm2/min

Maximum processing current: 7A

Number of control axes: 4 axes

Software: AUTOCUT

Working fluid: Special for wire cutting (emulsified soap)

Power supply: 380V220HZ

Maximum output power: 2.5kw

Mainframe dimensions: 1600 × 1240 × 1400mm

Product Description

Products feature

DK7745 high speed cutting 3/4/5 axis wire edm machine cnc edm machine wire cutting

Lu Young

Shandong Lu Young Machinery Co, Ltd. is established in July 1996.We are located in shandong provice.We are one of professional cnc lathe machine, cnc milling machine and swiss lathe machine manufacturer in china.We founded our fast lathe machine factory in 1996 in tengzhou City to produce center lathe and univesal milling machine for over 20 years development,we build three factories.One is for cnc lathe production one for cnc milling production.

We imported advanced production technology and R&D team from Korean in 2001 and build our third factory for swiss lathe machine production.We own about 500 wokers and 40 engineers, more than 5000 square meter .

We imported advanced production technology and R&D team from Korean in 2001 and build our third factory for swiss lathe machine production.We own about 500 wokers and 40 engineers, more than 5000 square meter .

Our engineer team have rich experiences for equipment selection and process design,we can give you professional solution based your workpieces fast and freely.We could product over 1000 sets cnc machine equipment one year. Our cnc machine tools has been exported over 40 countries and get good feedback.

♥Exported more than 40 countries.

♥ More than 300 staffs in factory.

♥ CE and ISO9001 certification .

♥ 7×24 hours online service.

Our service

DK7745 high speed cutting 3/4/5 axis wire edm machine cnc edm machine wire cutting

1. We supply 24 hours on-line service,you could contact with us by email ,phone ,wechat ,whatsapp,skype etc.

2. Received your phone or mail,we will Analyze the problem immediately.

3.Supply professional solution, after analyze the problem, we give you our best solution.

4. The warranty period of the whole machine is 1 year. Under normal use, if the machine parts are damaged during the warranty period, we will provide free accessories. Outside the warranty period, if the parts are damaged, we only charge the cost price of the parts, and will never overcharge.

5. Provide lifetime free technical support, you can contact us at any time if you encounter difficulties in the process of use.

6. We provide overseas services, engineers can go to the customer's factory for debugging,installation, maintenance, and repair. (In case of non-epidemic situation).

Packaging

DK7745 high speed cutting 3/4/5 axis wire edm machine cnc edm machine wire cutting

1.Port: Qingdao port or Shanghai port

2.Payment method: T/T, L/C, D/P, D/D etc.

3.Payment: 30% T/T as deposit, 70% balance shall be paid before shipment.

4.Delivery time: 30 days after receive the 30%T/T deposit.

5.Non-fumigation packaging, we use seaworthy plywood.

6. Steel base plate, it is stronger 3-5 times than normal plywood base plate.

7.Water-proof and damp proof, water resistant film wraped all the machine.

FAQ

1.Does the DK7745 high speed cutting 3/4/5 axis wire edm machine cnc edm machine wire cutting cnc lathe can be customized?

Of course, if our standard configuration can not meet your needs, please tell us that we redesign and produce the machine to meet your needs

2.How long is the warranty period of the DK7745 high speed cutting 3/4/5 axis wire edm machine cnc edm machine wire cutting?

Warranty period is one year, if parts damage within one year, we will send free of charge. Free online training or factory training to ensure that you can use our products properly. We can offer overseas paid installation, commissioning service.

3.What time is your work time?

We work online 24 hours a day, offer quotes and technical support at any time.

Of course, if our standard configuration can not meet your needs, please tell us that we redesign and produce the machine to meet your needs

2.How long is the warranty period of the DK7745 high speed cutting 3/4/5 axis wire edm machine cnc edm machine wire cutting?

Warranty period is one year, if parts damage within one year, we will send free of charge. Free online training or factory training to ensure that you can use our products properly. We can offer overseas paid installation, commissioning service.

3.What time is your work time?

We work online 24 hours a day, offer quotes and technical support at any time.

4.Do you use the Trade Assurance on Alibaba?

Yes, all of the order use this.Can guarantee the quality of the product and your payment.

Yes, all of the order use this.Can guarantee the quality of the product and your payment.

5.How to get a quote?

Please tell us the model you need or send us drawings of the workpiece, then we can recommend the most suitable products to you. We will give you the best offer within 24 hours.

Please tell us the model you need or send us drawings of the workpiece, then we can recommend the most suitable products to you. We will give you the best offer within 24 hours.

6.How to contact with you?

My mobile/whatsapp: +86 18660853235; QQ:3494630853 ;Please send message to us, thanks in advance!

My mobile/whatsapp: +86 18660853235; QQ:3494630853 ;Please send message to us, thanks in advance!