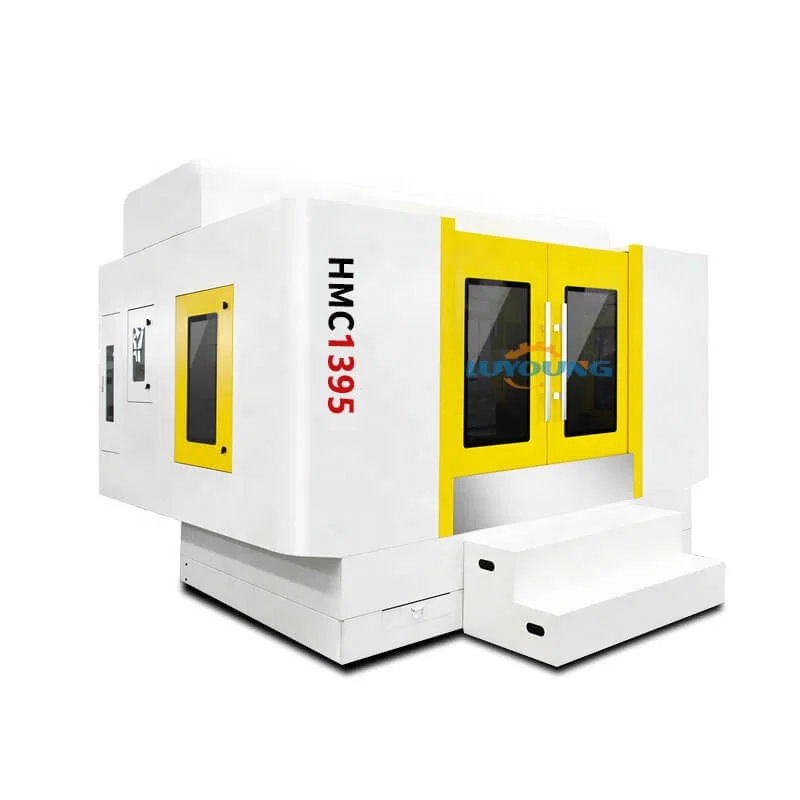

HMC1395 High Precision KND Controller Taiwan Spindle Cnc Vertical Milling Machine Horizontal Machining Center

Description

Product Description

HMC1395 high precision KND controller taiwan spindle cnc milling machine horizontal machining center.This machine tool can be used for precision machining of aerospace, automobiles, internal combustion engines, home appliances, and general machinery. It has good performance in completing the box hole system and plane processing during clamping, and is especially suitable for the turning and boring processing of box holes.

Specification of HMC1395 high precision KND controller taiwan spindle cnc milling machine horizontal machining center

| Description | HMC1075 | HMC1290 | HMC1395 | HMC 1814 |

| Worktable size(mm) | 1300×600 | 1360×700/ | 1400×700/ | 2000×900/ |

| 630*630 rotary table | 630×630 rotary table | 800*800 rotary table | ||

| Max loading weight on worktable( KG) | 800 | 1000 | 1000 | 1600 |

| T-slot(pieces-width-distance)(mm/piece) | 5-18-105 | 5-18-122 | 5-18-130 | 5-22-165 |

| X axis travel (mm) | 1000 | 1200 | 1300 | 1800 |

| Y axis travel (mm) | 750 | 800/600 | 800 | 1280 |

| Z axis travel (mm) | 600 | 700 | 750 | 900 |

| Distance from spindle end face to worktable center distance (mm) | 115-715 | 180-880 | 168-918 | 200-1100 |

| Distance from spindle center to worktable (mm) | 110-860 | 140-940 | 260-1060/0-800 | 140-1420 |

| Spindlespeed (r/min) | 6000 | |||

| X axis Rapid feeding speed(m/min) | 15 | 20 | 15 | 18 |

| Z axis Rapid feeding speed (m/min) | 15 | 20 | 15 | 18 |

| Auto Tool changer design | arm type auto tool changer | |||

| Auto Tool changer capacity (piece) | 24 | |||

| Accuracy test standard | JISB6336-4:2000/ GB/T18400.4-2010 | |||

| X/Y/Z axis Repeat positioning accuracy (mm) | ±0.005 | |||

| Gross weight (kg) | 8000 | 10000 | 10000 | 15000 |

Main configuration:

| Name | specifications | manufacturers | place of origin |

| Cnc control system | KND2000MF3i/HNC808DM | KND/Huazhong | Beijing/Wuhan |

| Servo drive and motor | System matching | KND/Huazhong | Beijing/Wuhan |

| Three axis bearing | Inside diameter 40, outside diameter 72 | SKF/NACHI | Switzerland/Japan |

| Three-axis ball screw (C3 grade) | X/Z:FD4012;Y:FD5010 | NMC/TEC | Taiwan |

| Three axis guide | X/Y:HGH45HA ; Z:HGH55HA; | HIWIN/ROLLON | Taiwan |

| tool changer | 24 arm type auto tool changer | OKADA/RELIB/DEX | Taiwan |

| belt type spindle | BT50-150-6000r/min | Volis/National Taiwan University/Okada | Taiwan |

| Booster Cylinder | 4.5T | Volis | Taiwan |

| Outer protective cover | 3700x3050x2700 | China | |

| 3 AXIS telescopic protection | Steel plate type | China | |

| pneumatic device | AIRTAC | Taiwan | |

| pressure switch | SMC | Japan | |

| cooling pump | CBK4-30/3 | Rocoi | Taiwan |

| Machine tool heat exchanger | HPW-10AF | China | |

| Main electrical components | Schneider/Delixi | France/China | |

| connection terminal | WAGO | Germany |

Product Feature

HMC1395 high precision KND controller taiwan spindle cnc milling machine horizontal machining center

Bed body:The bed body adopts integral positive T-shaped castings with good rigidity and precision retention. The exchange table and the tool magazine manipulator are fixed on the bed body to ensure the overall rigidity of the machine tool.The design of the bed body is analyzed by finite element, and its structure is reasonable and the ribs are arranged appropriately, so that it has sufficiently high static and dynamic rigidity and precision retention.

Column:The machine uses a dynamic column structure to move on the bed body. Its internal rib plate is analyzed by structural statics, dynamics and topology of finite cells.

Spindle box: The structure of the spindle box is analyzed by the structural statics, dynamics and topology of finite cells, and the reasonable structure design and the combination of reinforced ribs ensure the high rigidity of the box.

Dual switching workbench .The machine uses APC lift construction and direct swing. The whole process of work station exchange uses two sets of cam continuous motion for fast switching (exchange time: 12.5 seconds), which is very smooth and has very high reliability.

Worktable:The working table structure is very rigid after the structural statics, dynamics analysis and topological analysis of finite cells.

Spindle:The machine spindle has a two-speed internal variable speed electrical spindle structure with a maximum speed of 6000rpm. The customer can also select two internal variable speed spindles up to 12000 rpm. the spindle of the gear drive can also be configured according to customer requirements.

Screw:The X, Y and Z coordinate bars of the machine all use hollow strong cold technology, and the temperature of the cooling oil is controlled in real time, so that it changes in a small temperature range, thus reducing the thermal deformation of the screw in the process of cutting force and rapid movement, increasing the distortion stiffness of the screw, improving the processing accuracy of the machine tool, effectively reducing the inertia of the workstation's high-speed movement.

Guideline:X, Y, Z three coordinate guides using high-rigid self-lubricating roller straight rolling rail, good carrying performance, theuse of a straight-line rolling rail with a shelf to improve the rail life by 2.4 times. The roller rails have a self-lubricatingfunction and are self-injected with grease to maintain their lubrication performance for a long time.

Spindle box: The structure of the spindle box is analyzed by the structural statics, dynamics and topology of finite cells, and the reasonable structure design and the combination of reinforced ribs ensure the high rigidity of the box.

Dual switching workbench .The machine uses APC lift construction and direct swing. The whole process of work station exchange uses two sets of cam continuous motion for fast switching (exchange time: 12.5 seconds), which is very smooth and has very high reliability.

Worktable:The working table structure is very rigid after the structural statics, dynamics analysis and topological analysis of finite cells.

Spindle:The machine spindle has a two-speed internal variable speed electrical spindle structure with a maximum speed of 6000rpm. The customer can also select two internal variable speed spindles up to 12000 rpm. the spindle of the gear drive can also be configured according to customer requirements.

Screw:The X, Y and Z coordinate bars of the machine all use hollow strong cold technology, and the temperature of the cooling oil is controlled in real time, so that it changes in a small temperature range, thus reducing the thermal deformation of the screw in the process of cutting force and rapid movement, increasing the distortion stiffness of the screw, improving the processing accuracy of the machine tool, effectively reducing the inertia of the workstation's high-speed movement.

Guideline:X, Y, Z three coordinate guides using high-rigid self-lubricating roller straight rolling rail, good carrying performance, theuse of a straight-line rolling rail with a shelf to improve the rail life by 2.4 times. The roller rails have a self-lubricatingfunction and are self-injected with grease to maintain their lubrication performance for a long time.

Machine pictures

Our company

Shandong Lu Young Machinery Co, Ltd. is established in July 1996.We are located in shandong provice.We are one of professional cnc lathe machine, cnc milling machine and swiss lathe machine manufacturer in china.We founded our fast lathe machine factory in 1996 in tengzhou City to produce center lathe and univesal milling machine for over 20 years development,we build three factories.One is for cnc lathe production one for cnc milling production.

We imported advanced production technology and R&D team from Korean in 2001 and build our third factory forswiss lathe machine production.We own about 500 wokers and 40 engineers, more than 5000 square meter .

We imported advanced production technology and R&D team from Korean in 2001 and build our third factory forswiss lathe machine production.We own about 500 wokers and 40 engineers, more than 5000 square meter .

Our engineer team have rich experiences for equipmentselection and process design,we can give you professional solution based your workpieces fast and freely.We could product over 1000 sets cnc machine equipment one year. Our cnc machine tools has been exported over 40 countries and get good feedback.

♥ More than 20 years of production experience.♥Exported more than 40 countries.

♥ More than 300 staffs in factory.

♥ CE and ISO9001 certification .

♥ 7×24 hours online service.

Who choose us

The products have exported more than 40 countries around the world and receive many good feedback from our customer, please look who choose us:

our services

Our service of HMC1395 high precision KND controller taiwan spindle cnc milling machine horizontal machining center

1. We supply 24 hours on-line service,you could contact with us by email ,phone ,wechat ,whatsapp,skype etc.

2. Received your phone or mail,we will Analyze the problem immediately.

3.Supply professional solution, after analyze the problem, we give you our best solution.

4. The warranty period of the whole machine is 1 year. Under normal use, if the machine parts are damaged during the warranty period, we will provide free accessories. Outside the warranty period, if the parts are damaged, we only charge the cost price of the parts, and will never overcharge.

5. Provide lifetime free technical support, you can contact us at any time if you encounter difficulties in the process of use. 6. We provide overseas services, engineers can go to the customer's factory for debugging,installation, maintenance, and repair. (In case of non-epidemic situation).

Packaging

Packaging of HMC1395 high precision KND controller taiwan spindle cnc milling machine horizontal machining center

1.Port: Qingdao port or Shanghai port

2.Payment method: T/T, L/C, D/P, D/D etc.

3.Payment: 30% T/T as deposit, 70% balance shall be paid before shipment.

4.Delivery time: 30 days after receive the 30%T/T deposit.

5.Non-fumigation packaging, we use seaworthy plywood.

6. Steel base plate, it is stronger 3-5 times than normal plywood base plate.

7.Water-proof and damp proof, water resistant film wraped all the machine.

FAQ

1.Does the HMC1395 high precision KND controller taiwan spindle cnc milling machine horizontal machining centercan be customized?

Of course, if our standard configuration can not meet your needs, please tell us that we redesign and produce the machine to meet your needs

2.How long is the warranty period of the HMC1395 high precision KND controller taiwan spindle cnc milling machine horizontal machining center?

Warranty period is one year, if parts damage within one year, we will send free of charge. Free online training or factorytraining to ensure that you can use our products properly. We can offer overseas paid installation, commissioning service.

3.What time is your work time?

We work online 24 hours a day, offer quotes and technical support at any time.

Of course, if our standard configuration can not meet your needs, please tell us that we redesign and produce the machine to meet your needs

2.How long is the warranty period of the HMC1395 high precision KND controller taiwan spindle cnc milling machine horizontal machining center?

Warranty period is one year, if parts damage within one year, we will send free of charge. Free online training or factorytraining to ensure that you can use our products properly. We can offer overseas paid installation, commissioning service.

3.What time is your work time?

We work online 24 hours a day, offer quotes and technical support at any time.

4.Do you use the Trade Assurance on Alibaba?

Yes, all of the order use this.Can guarantee the quality of the product and your payment.

Yes, all of the order use this.Can guarantee the quality of the product and your payment.

5.How to get a quote?

Please tell us the model you need or send us drawings of the workpiece, then we can recommend the most suitable products to you. We will give you the best offer within 24 hours.

Please tell us the model you need or send us drawings of the workpiece, then we can recommend the most suitable products to you. We will give you the best offer within 24 hours.

6.How to contact with you?

My mobile/whatsapp: +86 18660853235; QQ:3494630853 ;Please send message to us, thanks in advance!

My mobile/whatsapp: +86 18660853235; QQ:3494630853 ;Please send message to us, thanks in advance!