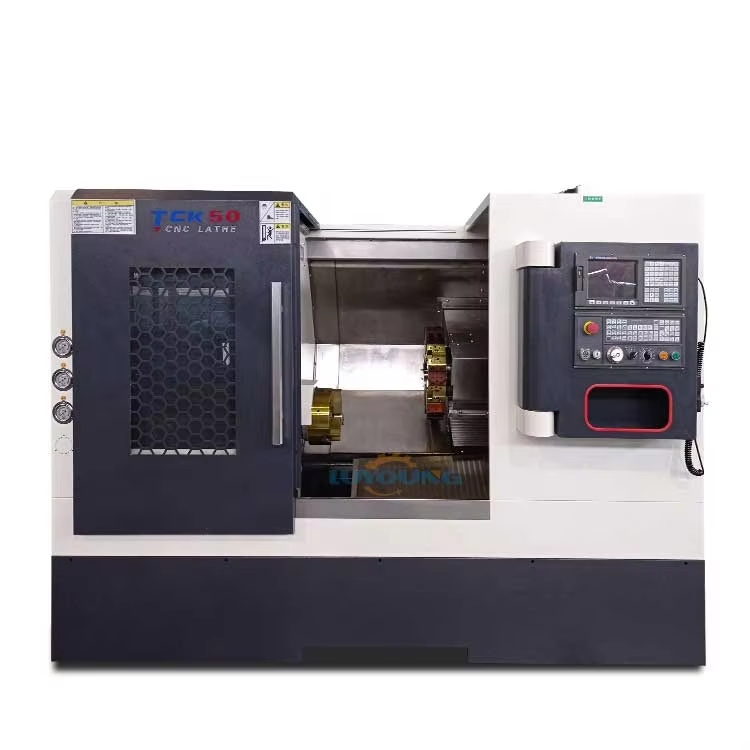

Heavy duty CNC lathe machines are essential tools for industries requiring high precision and durability. At Shandong Lu Young Machinery Co., Ltd., we pride ourselves on our state-of-the-art manufacturing processes that incorporate advanced technology, ensuring our machines meet the rigorous demands of modern manufacturing. Our heavy-duty CNC lathes are designed to handle large workpieces and complex geometries with ease. The integration of CNC technology allows for automated operations, reducing the risk of human error and enhancing production efficiency. Furthermore, our machines are equipped with user-friendly interfaces that facilitate ease of use, making them accessible even to operators with varying levels of experience. With our commitment to quality and customer satisfaction, we offer tailored solutions to meet your specific machining requirements, ensuring that you achieve optimal results in your production processes.