Description

PRODUCT SPECIFICATIONS

Products feature

1. The High Quality QK1327 QK1328 Horizontal CNC Lathe Pipe Threading Machine has the characteristics of high degree of automation, high efficiency and high precision, wide application range and simple operation .

2, CNC pipe screw lathe is my current more common lathe, for the medium CNC lathe in the boutique.

3. The headstock is driven by variable frequency motor with stepless speed change. Domestic well-known manufacturers spindle bearing, domestic well-known brand three jaw chuck.

4, CNC system modular design, easy debugging, easy maintenance, x,z axis using high-power, servo motor, advanced performance, strong reliability.

5, casting bed saddle. Skateboard, internal rib layout is reasonable, the selection of high-precision ball screw produced in Jining, high precision, accurate transmission. Domestic famous brand four-station electric tool holder, high positioning accuracy, strong rigidity, high reliability.

FEATURES AT A GLANCE

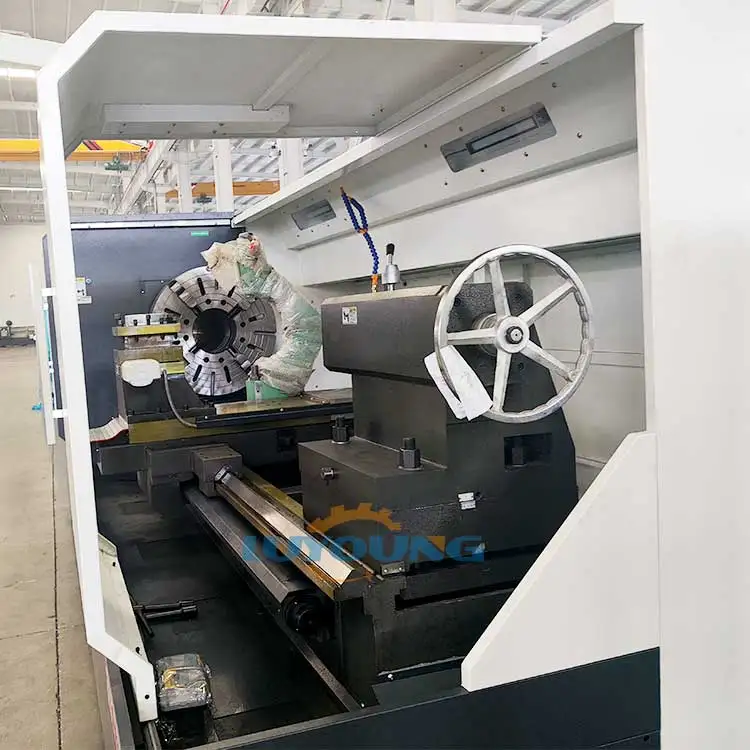

Left elevation

Front elevation

Right elevation

PRODUCT CONFIGURATION

| SPECIFICATIONS | Units | Q1319 | Q1322 | QK1327 | QK1328 |

| Swing over bed | mm | 630/800 | 630/800 | 800/1000 | 800 |

| Swing over cross slide | mm | 340/520 | 340/520 | 480/610 | 420 |

| Distance between centers | mm | 1500/3000 | 1500/3000 | 1000/1500/3000 | 1500 |

| Pipe threading range | mm | 50-193 | 50-220 | 130-270 | 130-280 |

| Guideway width | mm | 550 | 550 | 600/755 | 755 |

| Max. load capacity | kg | 3000 | 3000 | 4000 | 4000 |

| Spindle bore | mm | 200 | 230 | 280 | 220 |

| Spindle speed steps | - | /VF. 4 steps | /VF. 4 steps | VF. 4 steps | VF. 2 steps |

| Spindle speed range | rpm | 20-550 | 20-550 | 20-420 | 25-89/108-382 |

| φ800 4-jaw manual | |||||

| Chuck | mm | φ520/4-jaw manual | φ520/4-jaw manual | φ800 4-jaw manual | φ630 4-jaw manual |

| Turret/tool post | - | /Manual 4 position | /Manual 4 position | CNC turret 4 position | Electrical4 position |

| Tool shank size | mm | 32 x 32 | 32 x 32 | 32 x 32 | 32/40 |

| X axis travel | mm | 320/420 | 320/420 | 420 | 350 |

| 850/1350/2850 | |||||

| Z axis travel | mm | 1350/2850 | 1350/2850 | 850/1350/2850 | 1500 |

| X axis feed steps/range | mm/r | 22/0.02-0.45 | 22/0.02-0.45 | 40/0.05-1.5 | |

| Z axis feed steps/range | mm/r | 26/0.07-1.33 | 26/0.07-1.33 | 40/0.1-3.0 | |

| X axis rapid traverse | mm/min | 2300 | 2300 | 4000 | 4000 |

| Z axis rapid traverse | mm/min | 4000 | 4000 | 6000 | 6000 |

| Metric thread kinds /range | mm | 1———15 | 1———15 | 1-----30 | |

| Inch thread kinds /range | T.P.I | 14——1 | 14——1 | 28----1 | |

| Tailstock quill diameter | mm | 100 | 100 | 160 | 100 |

| Tailstock quill taper | - | MT5 | MT5 | MT6 | MT6 |

| Tailstock quill travel | mm | 250 | 250 | 250 | 250 |

| Main spindle motor | kw | 11 | 11 | 15 | 15 |

| Rapid traverse motor | kw | 0.3 | 0.3 | 0.3 | |

| Coolant pump motor | kw | 0.125 | 0.125 | 0.125 | 0.125 |

| Weight for 1500 | kg | 4300 | 4500 | 6200/6700/7700 | 4200 |

| Weight for 3000 | kg | 5500 | 5700 | ||

| Dimension for 1500 | mm | 3700x1550x1550 | 3700x1650x1550 | 3600/4100/5600x1930x1900 | 3750x1830x1900 |

Dimension for 3000 |

mm | 5200x1550x1550 | 5200x1650x1550 |

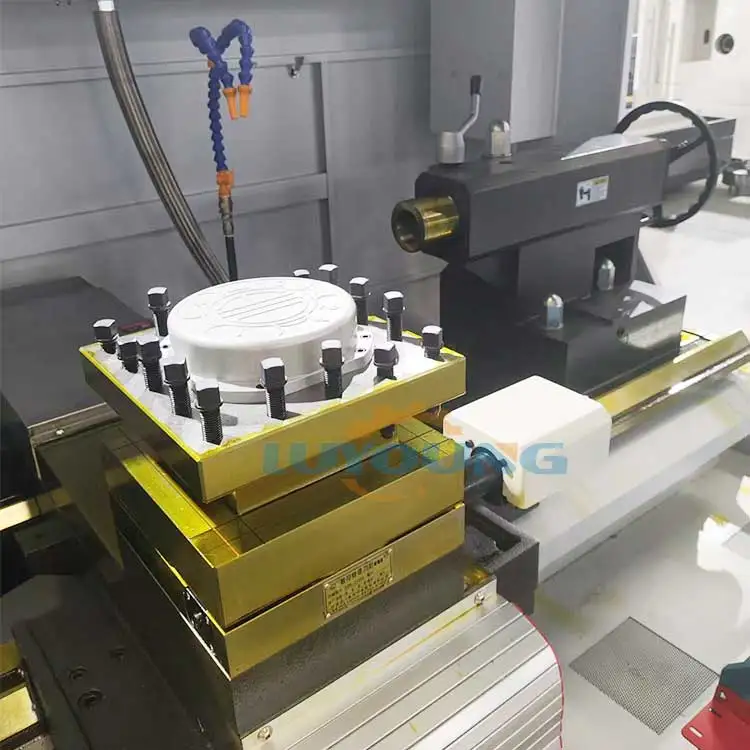

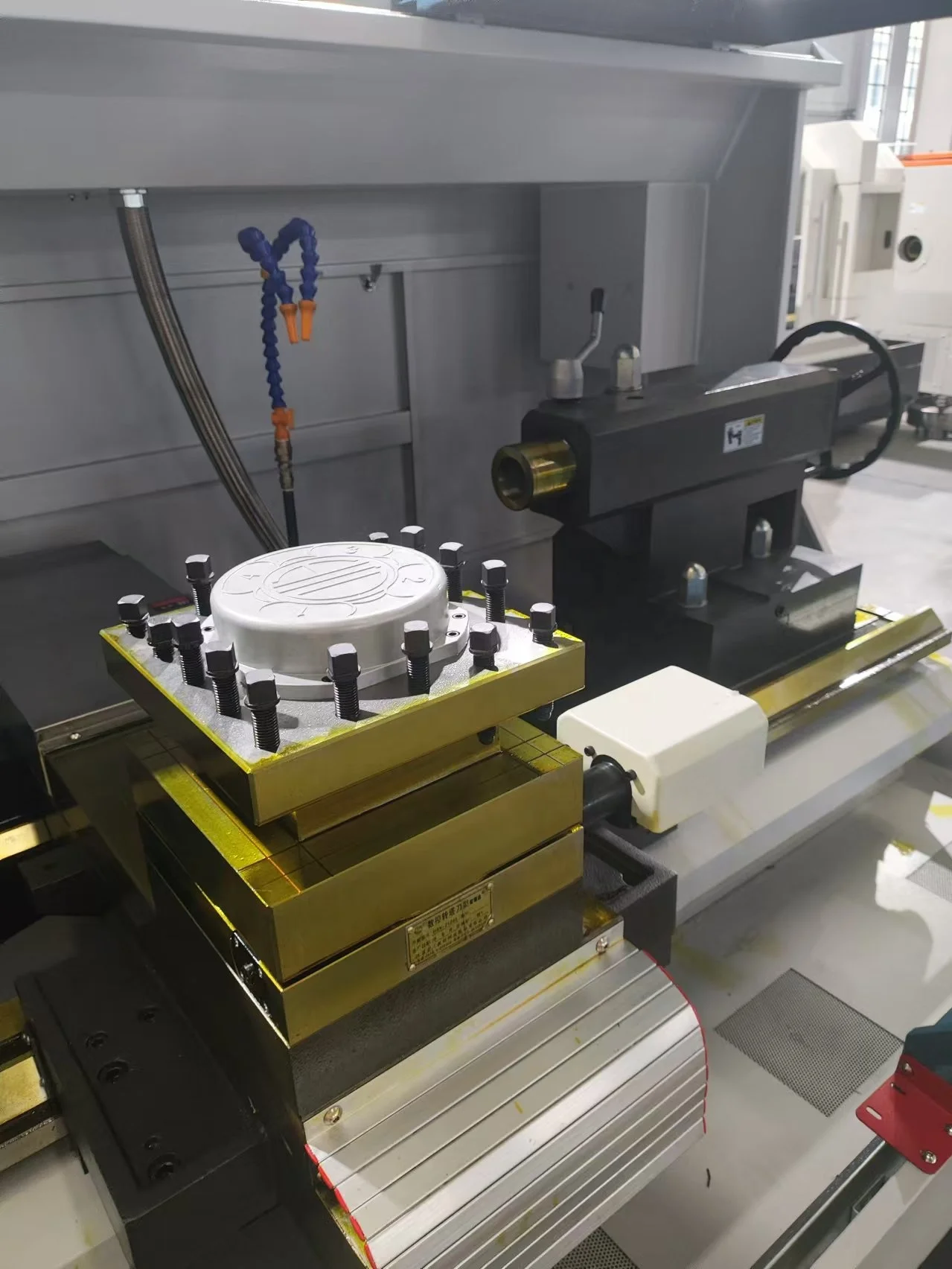

Chuck

4 station electrical tool holder

Manual tailstock

SALES AND SERVICE NETWORK

Successful Project

Project in China

Project in Indionsia

Project in Brazil

SIMILAR PRODUCTS

FAQ

Q1:Introduction about High Quality QK1327 QK1328 Horizontal CNC Lathe Pipe Threading Machine

A1:1.Port: Qingdao port or Shanghai port

2.Payment method: T/T, L/C, D/P, D/D etc.

3.Payment: 30% T/T as deposit, 70% balance shall be paid before shipment.

4.Delivery time: 30 days after receive the 30%T/T deposit.5.Non-fumigation packaging, we use seaworthy plywood.

6. Steel base plate, it is stronger 3-5 times than normal plywood base plate.

7.Water-proof and damp proof, water resistant film wraped all the machine.

8.Fully sheathed case,prevention of collision and keep the goods intact.

2.Payment method: T/T, L/C, D/P, D/D etc.

3.Payment: 30% T/T as deposit, 70% balance shall be paid before shipment.

4.Delivery time: 30 days after receive the 30%T/T deposit.5.Non-fumigation packaging, we use seaworthy plywood.

6. Steel base plate, it is stronger 3-5 times than normal plywood base plate.

7.Water-proof and damp proof, water resistant film wraped all the machine.

8.Fully sheathed case,prevention of collision and keep the goods intact.