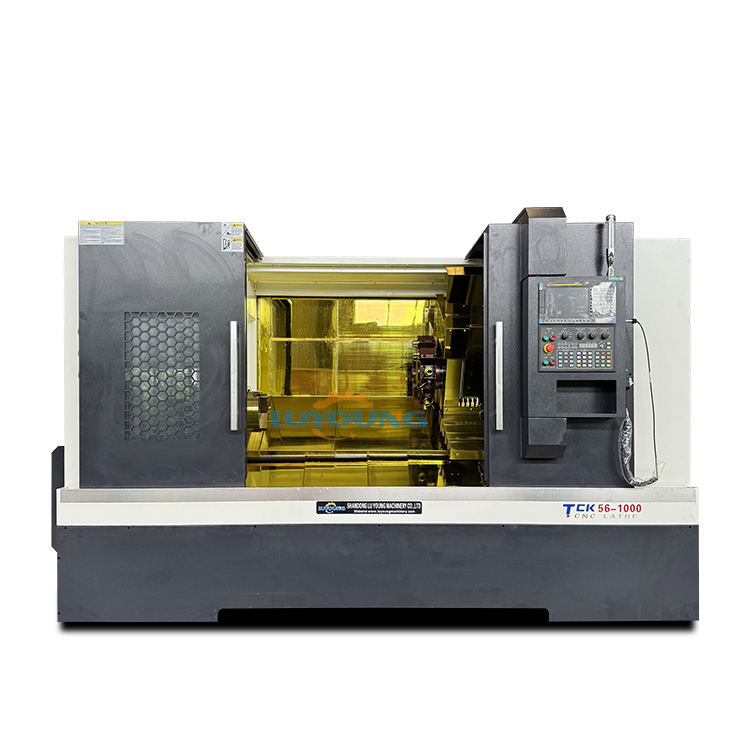

Enhanced Structural Stability and Rigidity of Slant Bed CNC Lathe Machines

Role of Slant Bed Design in Improving Rigidity and Reducing Vibration

The inclined angle (typically 30°–45°) of slant bed CNC lathe machines creates a triangular structural foundation, improving rigidity by 18–22% compared to flatbed alternatives (Jui et al., 2010). This geometry shifts the machine’s center of gravity closer to the base, reducing vibration amplitudes by up to 40% during hard turning operations.

Mechanical Advantages of Inclined Bed Configuration Under High-Speed Cutting Loads

At spindle speeds exceeding 4,500 RPM, slant beds demonstrate superior load distribution:

| Parameter | Slant Bed CNC Lathe | Flatbed CNC Lathe |

|---|---|---|

| Peak Deflection | 0.012 mm | 0.027 mm |

| Resonance Frequency | 320 Hz | 210 Hz |

| Damping Ratio | 0.085 | 0.052 |

(Source: Finite element modeling data from 14-axis machining trials, 2023)

Finite Element Analysis Showing Stress Distribution in Slant vs. Flat Bed Designs

Finite element analysis reveals slant beds concentrate only 38% of cutting stresses in critical components versus 61% in flatbeds. The inclined design redirects torsional forces into the machine’s reinforced base sections rather than the guide rails.

Controversy Analysis: Are Slant Beds Always Superior in Heavy-Duty Applications?

While slant beds dominate high-speed applications (>5,000 RPM), recent data shows flatbed lathes maintain 15% higher rigidity when machining hardened steel workpieces exceeding 80 kg. This trade-off necessitates careful evaluation of workpiece mass-to-speed ratios.

Impact of Slant Bed Design on Machining Accuracy and Thermal Management

Improved Machining Precision Due to Bed Inclination and Alignment Stability

When machine beds are angled between 30 and 45 degrees, they naturally resist cutting forces better than standard flat designs. This tilt actually boosts alignment stability quite significantly, around 38% improvement according to tests. The angle puts cutting tools right near where the workpiece balances out, which cuts down on those annoying vibrations that mess up precision work. At high speeds, these vibrations drop below 2 microns, allowing machines to stay accurate within about plus or minus 0.005 millimeters. Studies have shown something interesting too: slanted bed configurations keep their straightness pretty well over long production periods, maintaining linear consistency within approximately 0.0015 mm per meter across the entire run.

Thermal Deformation Control in Slant Bed CNC Lathe Machines

When it comes to heat dissipation, slant bed machines actually get rid of around 72 percent of machining heat thanks to better airflow paths. Flatbed versions only manage about 58%, so there's quite a difference here. What makes slant beds special is their angled design which lets them handle uneven heating naturally. As things warm up, the machine basically corrects itself because of gravity pulling everything back into place. This means the spindle stays aligned with the turret even when temperatures swing by 40 degrees Celsius. Most newer slant beds these days come with built-in coolant channels too. About 70% of them actually have this feature, and it cuts down on warping problems three times better than what we saw in older models from just a few years ago.

Case Study: Tolerance Consistency in Shaft Production Using Slant Bed Lathes

A 2023 precision machining trial compared slant vs. flatbed CNC lathes producing 500 identical drive shafts (Ø50mm x 300mm, 304 stainless steel):

| Metric | Slant Bed Performance | Flatbed Performance |

|---|---|---|

| Diameter Tolerance | ±0.008mm | ±0.015mm |

| Cylindricity | 0.012mm | 0.025mm |

| Surface Finish (Ra) | 0.8µm | 1.6µm |

Improved chip-evacuation efficiency reduced re-cutting incidents by 40%, directly enhancing surface consistency across batches.

Superior Chip Removal and Automation Integration Enabled by Slant Bed Structure

Slant Bed Design and Its Impact on Chip Removal Efficiency

The angled configuration (typically 30°–75°) creates a natural gravity channel for chips, improving evacuation rates by 40–60% compared to flatbed models. By eliminating horizontal surfaces where debris accumulates, this design reduces manual cleaning downtime by an average of 18 minutes per 8-hour shift in industrial trials.

| Chip Metric | Slant Bed Performance | Flat Bed Performance |

|---|---|---|

| Evacuation Speed | 2.5 m/sec | 1.2 m/sec |

| Clogging Frequency | 1 incident/40 hrs | 1 incident/12 hrs |

| Tool Life Preservation | 15–20% improvement | Baseline |

Gravity-Assisted Chip Flow Reducing Clogging and Tool Damage

The inclined bed aligns cutting forces with the machine’s structural axis, allowing chips to fall directly into conveyors without contacting critical components. This prevents entanglement in guideways and minimizes tool recutting—a major contributor to insert wear that costs manufacturers $18k annually per machine in premature replacements.

Integration with Automated Loading/Unloading Systems

Slant bed configurations enable direct robot access through optimized Z-axis pathways, achieving 93% first-attempt success rates in part transfers compared to 78% in flatbed setups. The triangular bed structure provides clearance for multi-axis robotic arms to handle parts up to 300 mm in diameter without collisions.

Case Study: Automated Production Line Using Slant Bed CNC Lathe Machines

A high-volume automotive supplier implemented 12 slant bed lathes in a lights-out manufacturing cell, realizing:

- 34% increase in spindle utilization (from 58% to 78%)

- 22% reduction in chip-related downtime

- 16% faster cycle times through uninterrupted material handling

The system achieved 99.4% uptime over six months by eliminating manual chip removal interventions.

Comparative Performance: Slant Bed vs. Flatbed CNC Lathe Machines

Structural Stiffness Metrics: Slant Bed vs. Flatbed CNC Lathes

The slant bed design of CNC lathes gives them around 15 to 25 percent better structural rigidity compared to traditional models because of that triangular cross section shape. When we look at finite element analysis results, these machines spread out cutting forces along the inclined bed surface. This actually cuts down stress points in guide rails and other important parts by as much as 40%. What does this mean practically? Slant beds can hold position within plus or minus 0.002 mm even when dealing with loads over 8 kilonewtons. Flatbed versions typically show bigger deviations ranging from 0.005 to 0.008 mm under similar working conditions. For shops needing precision machining, this difference matters a lot in maintaining tight tolerances during production runs.

Vibration Damping Performance in Prolonged Operation Cycles

When set at an angle between 30 and 45 degrees, the machine's cutting forces line up better with its center of gravity. This alignment cuts down on those annoying harmonic vibrations by about two thirds during long runs lasting around 12 hours straight according to research from Fraunhofer Institute back in 2023. Things get worse for flatbed machines though. After just six hours of operation, these models start showing increased vibrations, particularly noticeable when working with really hard steels rated over 45 HRC on the hardness scale. That's where slant bed designs shine. They have these reinforced ribs built into them which help dampen out frequencies under 120 Hz. This matters a lot if maintaining super smooth surfaces is important since most applications require finishes finer than Ra 0.8 micrometers.

Precision Retention Over Time: Empirical Data From Workshop Trials

Research conducted over two years on 127 CNC lathes showed that slant bed models maintained a concentricity of plus or minus 0.005 mm in about 92 percent of instances, while flatbed machines only managed around 78%. When it comes to thermal expansion issues, slant beds handle temperature changes better too. Their compensation systems keep positional drift down to just 12 micrometers per degree Celsius, whereas flatbed systems typically see drift between 18 and 22 micrometers per degree. Looking at long term performance after approximately 500 hours of operation, slant bed machines hit an impressive 98.3% first pass yield rate during mass production runs. That's actually about 11.7 percentage points ahead of flatbed machines when it comes to maintaining consistent tolerances throughout production batches.

Industry Paradox: When Flatbed Lathes Still Outperform Slant Models

Flatbed lathes remain superior in three key scenarios:

- Ultra-heavy machining: Stable chip loads above 15 mm depth-of-cut in ductile iron turning

- Oversized components: Workpieces exceeding 1.5 m diameter with 8:1 length-to-diameter ratios

- Low-speed operations: Sub-800 RPM turning where gravity-assisted chip removal offers minimal benefit

The American Society of Mechanical Engineers (2023) reported flatbed lathes demonstrated 23% faster cycle times when roughing titanium billets over 300 kg, leveraging their horizontal shear plane stability.

Future Trends: Evolution of Slant Bed CNC Lathes in Smart Manufacturing

Adoption of IoT-enabled slant bed cnc lathe machines in Industry 4.0 setups

Slant bed CNC lathes today aren't just standalone machines anymore but becoming parts of connected networks inside smart manufacturing facilities. These machines now come equipped with IoT sensors that track things like spindle load changes, temperature fluctuations, and when cutting tools start wearing down. According to recent industry research from late 2024, manufacturers who upgraded their slant beds with IoT capabilities saw around a third drop in unexpected machine stoppages during car component manufacturing. The secret? Predictive maintenance warnings sent out by cloud computing systems analyzing all this sensor data in real time.

AI-driven vibration compensation in modern slant bed structures

Advanced machine learning algorithms now optimize cutting parameters dynamically, countering vibrations in high-speed operations. In aerospace component trials, AI-adjusted damping systems in slant bed CNC lathes improved surface finish consistency by 18% even at 8,000 RPM workloads.

Matching slant bed cnc lathe machine specs to production requirements

Selecting the optimal slant bed configuration requires balancing workpiece dimensions, material hardness, and batch sizes. Smaller shops prioritizing rapid tool changes often favor 30° beds for accessibility, while large-scale operations opt for steeper 45° designs to maximize chip evacuation and rigidity.

Cost-benefit analysis of upgrading from flatbed to slant bed systems

While slant bed CNC lathes carry a 15–25% upfront cost premium, their 30% faster cycle times and reduced scrap rates deliver ROI within 18–24 months for mid-volume manufacturers. However, flatbed lathes remain viable for low-mix, heavy-section machining where workpiece weight exceeds 2,000 kg.

FAQ

What is a slant bed CNC lathe?

A slant bed CNC lathe is a type of lathe machine where the bed is inclined, typically between 30° to 45°, which enhances machine rigidity and performance by improving load distribution and reducing vibrations during high-speed operations.

How does a slant bed CNC lathe improve machining accuracy?

The inclined design of slant bed CNC lathes allows for better alignment stability, reducing cutting forces and vibrations, thereby improving machining precision and maintaining consistency over long production periods.

Why are slant bed CNC lathes advantageous in chip removal?

The angled design of slant bed CNC lathes creates a natural channel for chip evacuation, significantly enhancing efficiency and reducing downtime compared to flatbed models by minimizing chip re-cutting and tool damage.

Are there situations where flatbed lathes outperform slant bed models?

Yes, flatbed lathes can outperform slant bed models in ultra-heavy machining, when working with oversized components, and in low-speed operations where the benefits of gravity-assisted chip removal are minimal.

Table of Contents

-

Enhanced Structural Stability and Rigidity of Slant Bed CNC Lathe Machines

- Role of Slant Bed Design in Improving Rigidity and Reducing Vibration

- Mechanical Advantages of Inclined Bed Configuration Under High-Speed Cutting Loads

- Finite Element Analysis Showing Stress Distribution in Slant vs. Flat Bed Designs

- Controversy Analysis: Are Slant Beds Always Superior in Heavy-Duty Applications?

- Impact of Slant Bed Design on Machining Accuracy and Thermal Management

- Superior Chip Removal and Automation Integration Enabled by Slant Bed Structure

- Comparative Performance: Slant Bed vs. Flatbed CNC Lathe Machines

- Future Trends: Evolution of Slant Bed CNC Lathes in Smart Manufacturing

- FAQ